The markets of wine, beer, spirits, juices and soft drinks are constantly evolving, and the technological solutions adopted for the filtration of liquids must keep up with innovation and growth. VLS Technologies represents worldwide a single reference point for the client for both the aspect of filtration and more complex needs that involve the whole process of liquid treatment: that is made possible by the production plant in San Zenone degli Ezzelini in the Province of Treviso, northeast Italy, as well as by an established worldwide network of agents, authorized reselling and assistance. In addition to traditional applications, as sheet filters or pressure leaf filters, the focus of VLS Technologies is the development of innovative solutions as cross-flow filtration systems and reverse osmosis.

The markets of wine, beer, spirits, juices and soft drinks are constantly evolving, and the technological solutions adopted for the filtration of liquids must keep up with innovation and growth. VLS Technologies represents worldwide a single reference point for the client for both the aspect of filtration and more complex needs that involve the whole process of liquid treatment: that is made possible by the production plant in San Zenone degli Ezzelini in the Province of Treviso, northeast Italy, as well as by an established worldwide network of agents, authorized reselling and assistance. In addition to traditional applications, as sheet filters or pressure leaf filters, the focus of VLS Technologies is the development of innovative solutions as cross-flow filtration systems and reverse osmosis.

Innovative technologies guarantee a number of advantages. For example in cross-flow filtration the liquid is pushed by means of pressure through the particular pores of a membrane: thanks to this system the clients are able to improve the obtained quantity of product, decreasing energy consumption and production costs, for example avoiding the usage of clarifiers and adjuvants.

Cross-flow filtration for every need: Unico filter

Unico filter is the new solution by VLS Technologies dedicated to small and medium producers. Differently from the other technologies available on the market, Unico is an all-in-one solution that enables to filter lees and musts together perfectly filtering them in a single step. The result is a filtered product of excellent quality with a turbidity below 1 NTU. Thanks to Unico it becomes possible to get a good filtration of the product and to reduce the microbiological flora; all of this by saving all the organoleptic characteristic of the product. The filtering media can stand repeated regenerations with warm water and detergents: this means a longer lifespan. At the end of the process, the remaining product in the tank does not have to be reprocessed and can be sent directly to the distillery in order to optimize time, product and resources. Unico filter implements two types of membranes: the capillary membranes made of polyethersulfone that guarantee a perfectly clean product and the stainless steel membranes. The all-in-one filtration solution Unico by VLS Technologies has been awarded the New Technology SIMEI 2017 in the Innovation Challenge SIMEI@drinktec 2017.

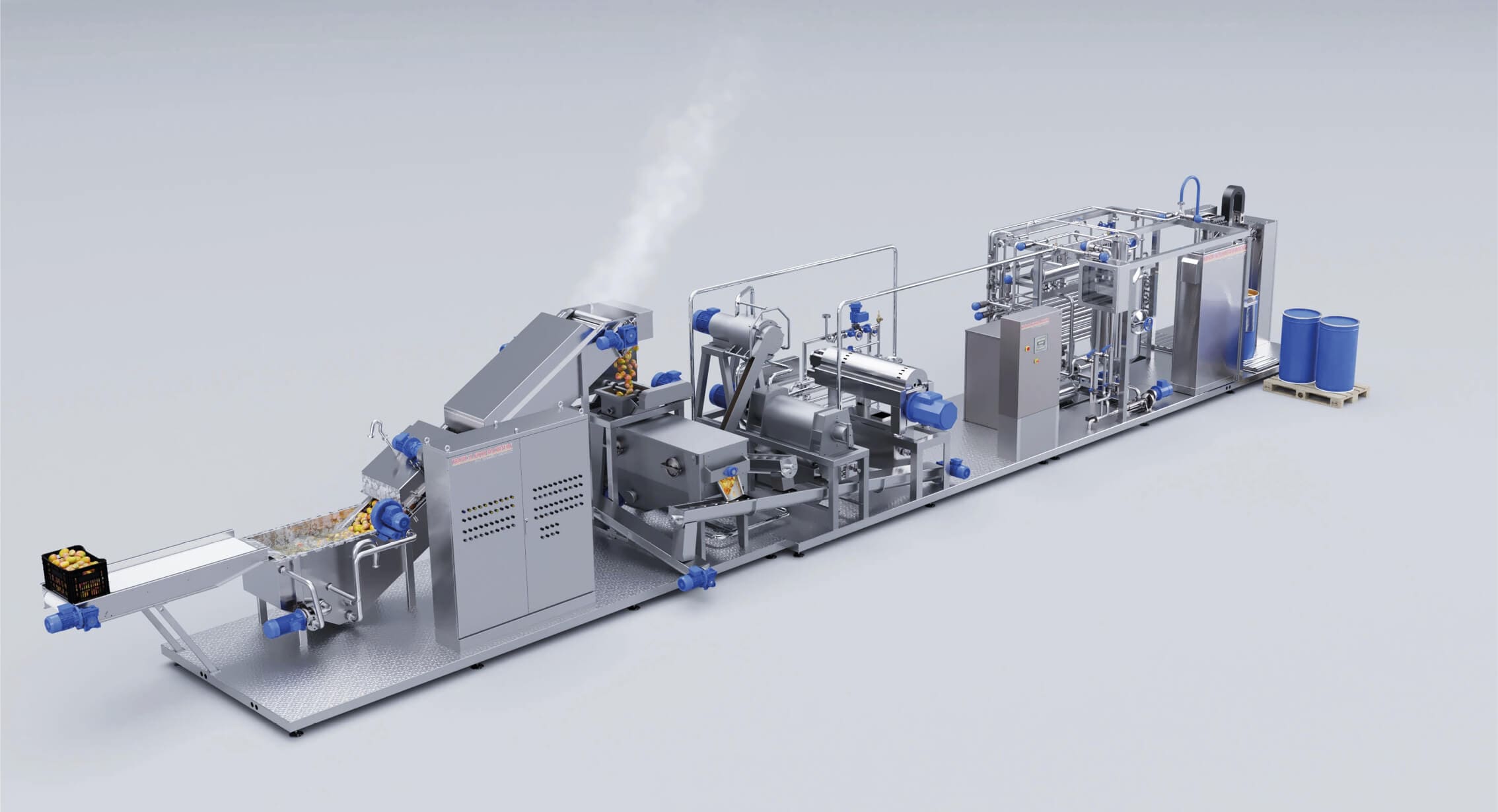

Lees-stop filter: “difficult” productsare no longer a problem

Lees-stop, winner of the New Technology Award at SIMEI 2015, is a solution meant for filtering products with high content in solids that replaces the traditional polymeric membranes of the cross flow filters with sinterized stainless steel membranes. Thanks to several tests, VLS has verified that this kind of material perfectly fits the cross flow filtration of “difficult” products with about 70% of content in solids. This membrane has the characteristics to be long lasting and resistant to pressure, temperature and chemical products. Those features are as many assets for the reliability of the filtration and the capacity of regeneration of the membranes. Clogging is contained on the surface of the membrane which allows for more consistent removal of solids from filterable area, thus allowing for longer, more productive filter cycles. The filter is more productive than a classical rotary drum vaccum filter, and will not lose quality or alcohol. Moreover, residues, still containing alcohol, can easily be valorized in a distillery. Lees – Stop Filter exists with 2, 3, 4, 5, 6, 7 and 8 membranes.

Lees-stop, winner of the New Technology Award at SIMEI 2015, is a solution meant for filtering products with high content in solids that replaces the traditional polymeric membranes of the cross flow filters with sinterized stainless steel membranes. Thanks to several tests, VLS has verified that this kind of material perfectly fits the cross flow filtration of “difficult” products with about 70% of content in solids. This membrane has the characteristics to be long lasting and resistant to pressure, temperature and chemical products. Those features are as many assets for the reliability of the filtration and the capacity of regeneration of the membranes. Clogging is contained on the surface of the membrane which allows for more consistent removal of solids from filterable area, thus allowing for longer, more productive filter cycles. The filter is more productive than a classical rotary drum vaccum filter, and will not lose quality or alcohol. Moreover, residues, still containing alcohol, can easily be valorized in a distillery. Lees – Stop Filter exists with 2, 3, 4, 5, 6, 7 and 8 membranes.

Dead-end filtration: Pluma filter

Pluma filters are micro-filtration cartridge technologies that can treat the product avoiding the usage of adjuvant substances. The technology is completely realized with stainless steel (AISI 304 or AISI 316), is equipped with PLC for the managementand monitoring of the operation and washing stages, housing for filtering cartridges, pumps and tools for the correct operation. Pluma filters are available both automatic and semi-automatic. One of their advantages is represented by the possibility to use cartridges with different porousness that make possible to filter in various steps to obtained the requested density. The range goes from 3 to 30 cartridges but on request different sizes are available. All Pluma filters are made of food-grade stainless steel and placed on a stainless steel skid with adjustable feet or wheels. Plants are completed with pumps, housings and instrumentation necessary for correct functioning and control of all security parameters. Each plant is completed with pressure transducers, electrical flow meter, temperature sensing probe, control of the flow of the feeding pump, tank for water and pump for washing. VLS Technologies, thanks to its 35-year experience in the market, can guarantee a dynamic and flexible approach, realizing long-term partnerships with both medium and small production companies as well as well as with major brands worldwide.

www.vlstechnologies.it