AcmaVolpak at Interpack: flexible solutions for the Fast Moving Consumer Goods market

INTERPACK 2014

[twitter-follow screen_name=’itfoodonline’]

Tweet

Tweet #interpack 2014

For info please contact +39 0362 244182, or mail to info@itfoodonline.com.

AcmaVolpak, part of the Coesia Group, will exhibit some of its latest solutions for fast moving consumer goods sectors, including Tea & Coffee, Bakery, Beverages, Food, Confectionery & Chocolate products, Home and Personal Care.

AcmaVolpak, part of the Coesia Group, will exhibit some of its latest solutions for fast moving consumer goods sectors, including Tea & Coffee, Bakery, Beverages, Food, Confectionery & Chocolate products, Home and Personal Care.

Among the many novelties on show, the company will present some of its finest solutions dedicated to the fast moving consumer goods, namely the Acma SP1 flowpacker and the horizontal form-fill-seal machine Volpak SC-140. The two machines are a perfect examples of AcmaVolpak construction approach, which aims to merge high end performances with great efficiency, energy saving and reliability. Other solutions on show will be the Acma M888 multy-style wrapping machine, the Enflex STD-22 for stand-up pouches and Volpak SI-280. First time on show also for the T4 Modula, Tecnomeccanica’s new solution for packaging tea in filter bags. Last but not least, the company will present a complete packaging line for coffee capsules, which will consist of a series of fully integrated machines: the Qi for capsule filling and the MiniWrap. Such innovative packaging line will also include a cartoner and some state of the art solutions for industrial processing.

ACMA MACHINES T4Modula

ACMA MACHINES T4Modula

Designed and manufactured by Tecnomeccanica – the brand dedicated to the tea market

– T4 Modula is AcmaVolpak’s new, medium-speed, tea bag machine. It consists in a double chamber “knotted” packaging solution, particularly appreciated in worldwide markets as it guarantees users with the highest product authenticity and aroma. In addition to its performance in line with its category (T4 can package up to 250 bags per minute), this new solution by AcmaVolpak is particularly advanced in terms of sustainability and materials saving. The tea bag packaged by T4, which could be defined within the most beautiful in the world, is produced in non heat-sealed filter paper, it is 100% biodegradable and is closed without using any metal staple in order to better preserve the genuineness of its content. An octagonal tag is placed on the front of the bag, while the string is attached underneath; these features make the tea bag aesthetically more pleasant and optimise brand visibility, thus supporting the customer’s marketing strategies.

Qi

Qi

Qi is designed to fill rigid and semi-rigid capsules. It guarantees a high production rate (the line’s speed may be 140, 350 or 500 pieces per minute). Acma’s capsule processing machine, thanks to the design of the batchers on independent stations, guarantees maximum precision in controlling the weight in the filling phase (the precision tolerance is less than 0.1 gr. per capsule). It is also pre-arranged for vacuum directly inside (in the configurations from 350 and 500 ppm), required to extend the product’s shelf life. During the design phases, special attention was paid to reducing the consumption of capsule assembly materials; for example, initial tests on the material used to seal the upper part of the capsule (or insert the filter paper inside it) indicate a reduction in waste paper and savings of 48% (depending on the diameters) as opposed to the conventional machines. The central core of the system is its transfer unit, which develops horizontally; by exploiting the full perimeter of the machine, the overall spaces are minimized and the production flow can be set clockwise or anti-clockwise according to the layout requirements of the production area. This also means that it is possible to employ just a few operators on several machines who can supervise one or more lines.

MiniWrap

MiniWrap

MiniWrap wraps capsules and pods guaranteeing a significant production rate. Tight wrapping results are achieved by mean of dedicated induction sealers, customized folding devices, vacuum and Nitrogen injection system. Incredible reduction of wrapping material (up to 40%), together with tightness wrapping offer the possibility to reduce also the dimension of the cartons and cases with important savings in both material costs and logistic. A wide range of optional applications further optimize machine performances

M888

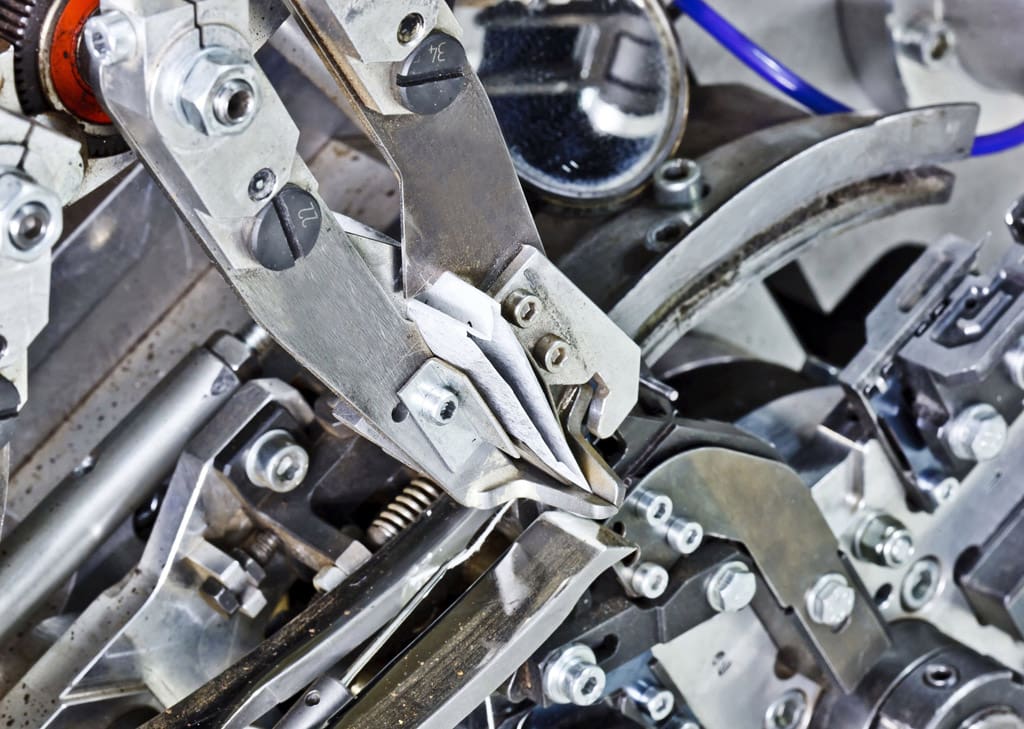

Patented multi style automatic wrapping machine, suitable for a wide range of pre-formed candies and chocolate products with flat bottom, it can handle also soft toffee like korovka. The multi style wrapper model M888 combines the benefit of continuous motion in-feed system, namely higher speed and sensitivity in handling the product during the first wrapping phases, with those of indexing motion, offering greater precision during the final wrapping process and high flexibility to move from one style to another. The wrapping style and size changeover can be accomplished in less than 60 minute. Thanks to the cantilevered architecture the M888 offers a very high accessibility for easy maintenance and cleaning. The machine can make the following packaging styles: bon bon viennoise, double twist, fancy, bunch and portfolio; gianduiotto is coming soon.

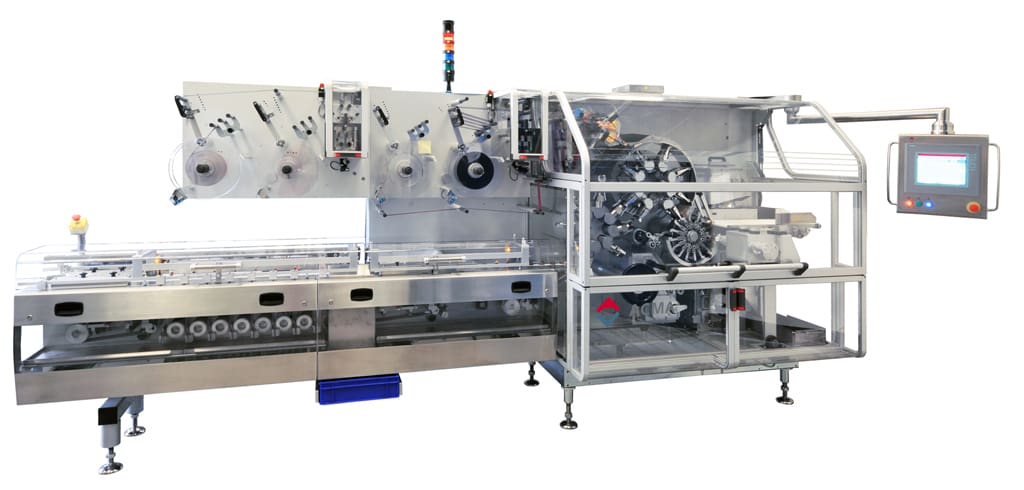

SP1

Acma is able to offer the market a full range of technologically leading-edge machinery that successfully fits into new or existent production lines to package loose and horizontally and vertically stacked products in single wrap or multipack format. Acma’s offer includes three different models of flow packers: SP0, SP1 and SP2, designed around four fundamental principles: performance, simplicity, flexibility and sustainability. Acma does not just commercialise wrapping machines, but is indeed able to provide its customers with distribution and infeed systems to manage product alignment and machine infeed, on one or more lines. The modular distribution systems designed by Acma manages incoming products arranged in rows aligned by the process line with great efficiency. Some automatic applications are also available to feed one or more packaging lines: for example: a biscuit or cracker packaging line can be divided, by feeding a first machine for packaging in stacks and a second for packaging in “slugs”. By means of horizontal or vertical loaders, the product is subsequently transferred to the infeed system. The machine infeed systems are driven by independent brushless motors and guarantee particularly delicate product handling, at the same time allowing easy access to the various components thanks to the cantilevered design, which translates into ease-of-use and hygiene simplicity. The flow packers of Acma SP series pack single products or multipacks at medium and high speeds, with hot or cold sealing system: the rotary sealing unit can also be supplied in the “Long-dwell” version, which thanks to its traversing movement during the sealing phase, allows to process particularly resistant materials at high speed that have to guarantee a totally airtight seal of the package. The wrapping film unwinding system is equipped with an automatic splicer, so that the reel can be replaced quickly without having to shutdown the machine.

VOLPAK MACHINES STD-22

The open design and the accessibility to all of the mechanisms convert the STD-22 into the ideal equipment for the client who looks for ease of use and low maintenance cost. You can manufacture Stand Up type pouches, with front, lateral or well centered caps in the upper sealing, sachets with different shapes, reaching a production output of up to 140 sachets per minute. Thanks to its versatility, it is the ideal machine for affronting a great variety of projects; from dehydrated soups with or without pasta and vegetables, to grated cheese, sauces, juices, dairy products, etc. Available with zipper applicator, corner and top cap fitment.

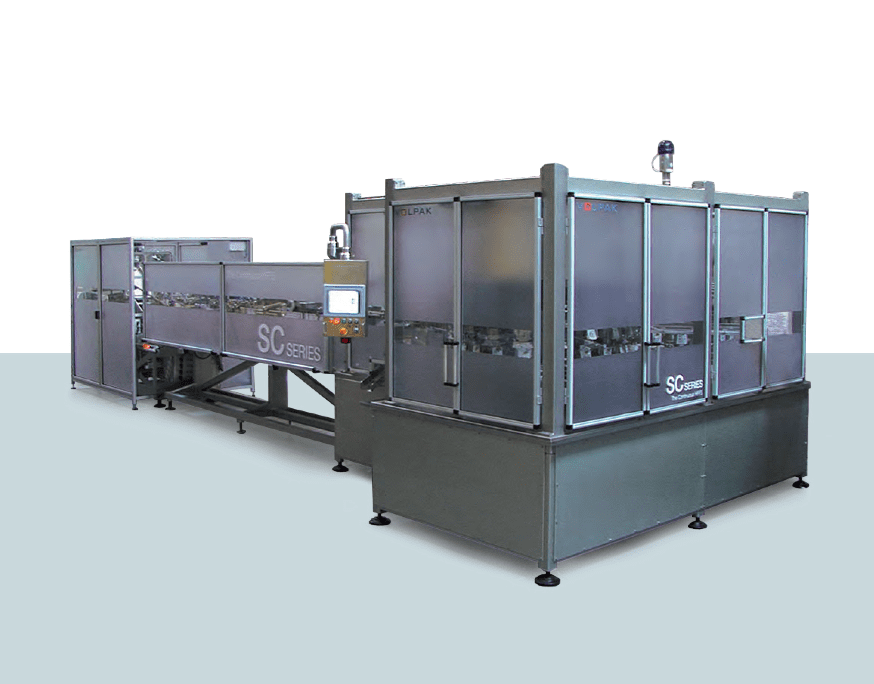

SC-140

With the SC series, Volpak presents the new range of HFFS machines with continuous motion technology doubling the production rates. The Volpak SC series is based on two platforms, for pouches up to 500ml and 1500ml capacity, that cover the needs of the world-wide market for flexible pouches. With the new SC series customers can double their production capacity benefiting from important savings in energy, maintenance, packaging cost and space. The machine also uses a linear pouch forming module, guaranteeing the seal integrity and quality of the pouches produced and a continuous carrousel, featuring a modular build concept, equipped with different turrets for pouch opening, filling, capping and top sealing, depending on project configuration. The single fill station and the gentle handling of the pouches are key to optimize the filling conditions for any type of product. Finally, the top seal turret allows operating in optimum conditions, and is designed to accommodate pouches with or without caps. SC is available in two versions, depending on the format and volume of the pouches and in many configurations: for liquid products with or without reclosable caps and for dry products with or without re- closable zippers.

SI-280

Availability, Performance and Quality, the three pillars for the development of the new SI series, designed to maximize Overall Equipment Effectiveness. The new SI-280 offer the possibility of producing larger pouch formats and even working in triplex, with all the advantages of the SI series. The new SI turns changing format into a controlled process by guiding the operator and leaving no room for improvisation.

We look forward to welcoming you to Interpack 2014, Hall 6 D31 E57

ACMAVOLPAK is a leading manufacturer of packaging machines in the consumer goods market, with a large international share. Designs and manufactures automatic packaging machine for the following sectors: Confectionery and Chocolate, Bakery, Food and Dairy, Beverage, Tea and Coffee, Pet Food, Personal Care, Home Care, Chemical e Pharma. ACMAVOLPAK headquarters is located in Bologna (Italy) and Barcelona (Spain). ACMAVOLPAK is part of COESIA, a group of innovation-based industrial solutions companies operating globally with direct organization locally distributed and headquartered in Bologna, Italy.