Also in the Food Industry, Air Motors are excellent solutions, exploiting the use of compressed air, that can be used as integrable components on machinery or to hand tools, and can be therefore effective in numerous applications. Their use in the Food Sector is, in fact, really heterogeneous, being incorporated into machinery to stir substances or liquids, to mix, to drive clipping machines in meat processing or to cap recipients.

The Case Study described by Mr. Nicola Pellizzari, Fiam Group’s Product Manager for Air Motors, and related to a company in the Food Industry producing synthetic casings, refers to this specific function. In fact, the above-mentioned synthetic casings, used to cover cured meats, have to be kept in appropriate jars, immersed in a 25 % saltwater solution for their perfect/proper preservation.

The customer was looking for an effective technology that could eliminate the manual work of closing the lids of plastic jars in the production line, thus optimizing production operations even at this stage.

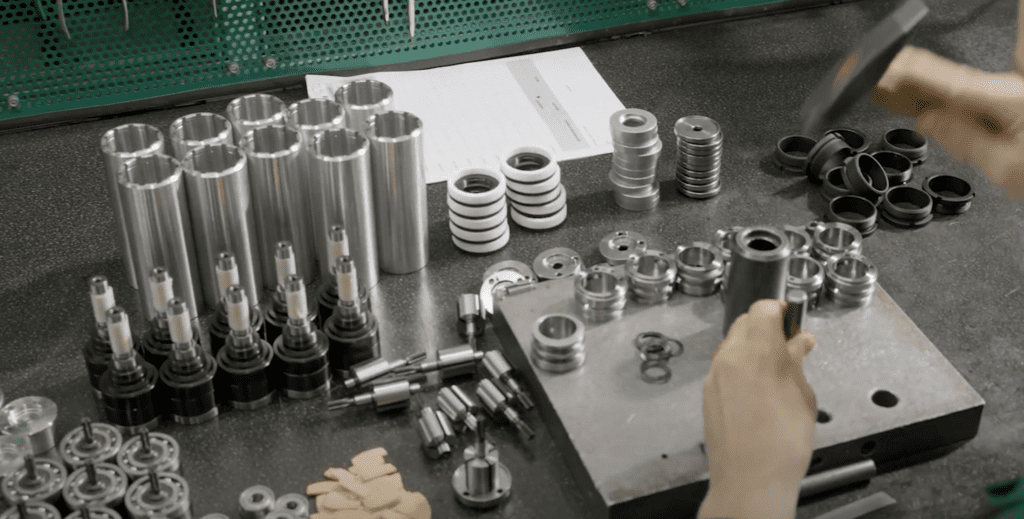

For this purpose, Fiam has designed and produced a customized air motor to be combined with a capping head, with the function of rotating it to tighten the plastic lid of casing jars. The capping is done by taking advantage of the stall torque of the air motor.

Considering the highly humid and corrosive environment, the customer discarded from the beginning the idea of installing an electric motor, to avoid short circuits that would be created due to the presence of a high percentage of humidity, and secondly, to avoid corrosive phenomena resulting from the presence of water and salt in the solution contained inside the jars containers.

The application involved an air motor made with an outer casing of plastic material of the type of POM C Ertacetal, a material that gives high mechanical strength as well as excellent dimensional stability. In addition, stainless steel AISI316 has been used for the output shaft in order to definitively avert the risk of corrosive phenomena.

From this Case Study we can see the main advantages of an Air Motor for Food machinery, an industry characterized by high humidity and with strict cleaning and sterilization requirements, for which Motors have all the necessary features:

• IP67 degree of protection that prevents water/steam/dust from entering the motor and damaging it

• Safe and reliable operation even at high temperatures

• High corrosion resistance due to galvanic treatments that make them highly resistant to aggressive agents

• Fabrication with high-quality stainless steel according to ISO standards

• Gears lubricated with food-grade lubricant

• Cavity-free outer surfaces that prevent dust and dirt accumulation and ensure ease of cleaning and sterilization

Not only Fiam offers a wide catalog range of models in the stainless steel version with IP67 Protection and with ATEX Certification, perfect for application in the Food industry, but there are also numerous “unique” customized solutions, often designed together with the customer in co-engineering mode. A truly important aspect of distinction of Fiam and our R&D.