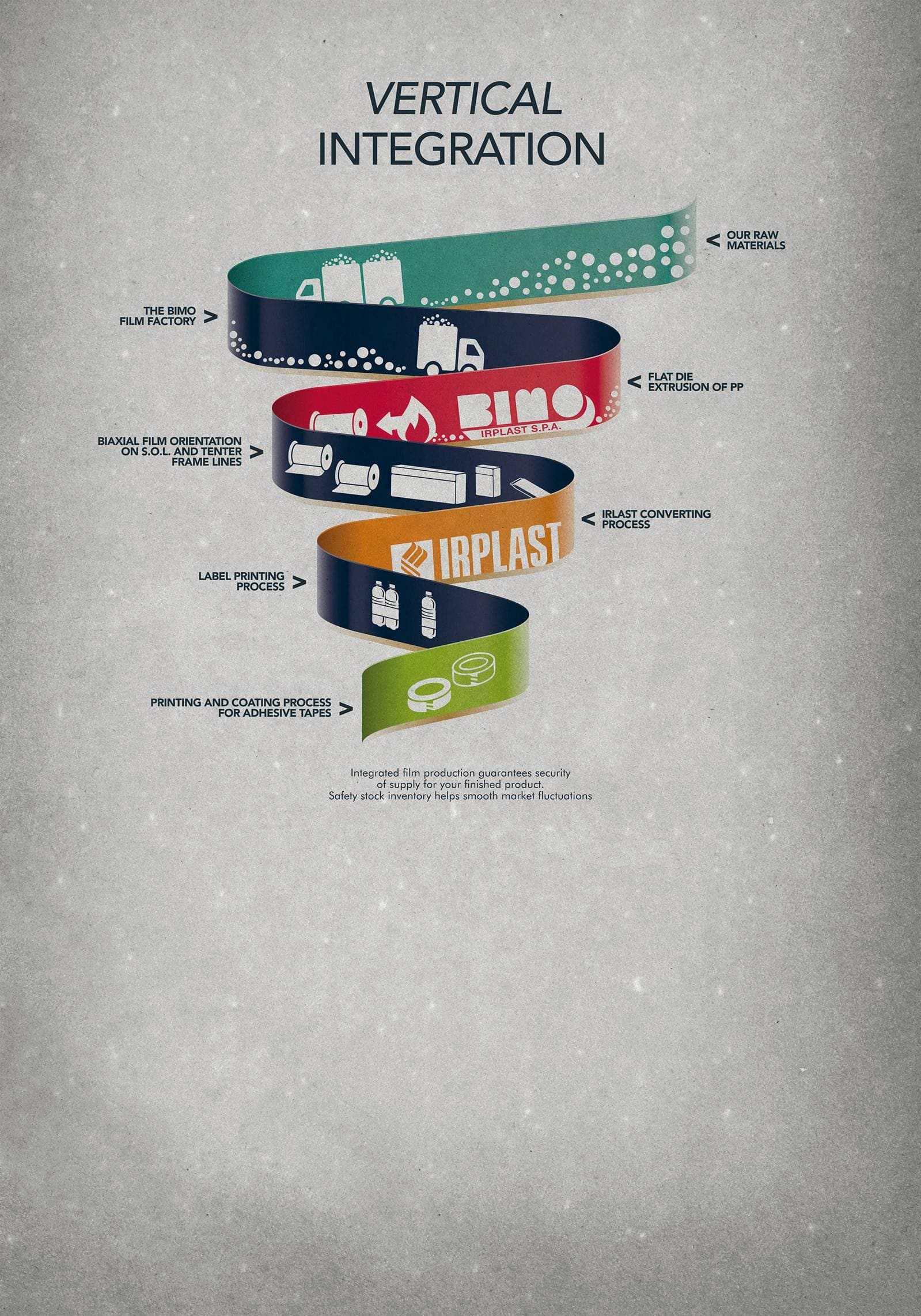

BOPP manufacturer Bimo was set up in the mid 1980s by the Tuscany-based Irplast Group. Today Irplast is an Italian industrial group vertically integrated (production of bi-oriented polypropylene film by BIMO subsidiary and printed adhesive tapes and labels by Irplast), operating in Food, Beverage, Tobacco and Toiletries industrial areas. The company reaps the advantages offered by integration to create unique opportunities for rapid and targeted R&D initiatives on films, thanks to the possibility of immediately testing in-house the conversion and application performance of the new products. The Bimo division operates two BOPP film production sites in Atessa (CH) and Irplast operates a film printing and coating plant in Empoli (FL).

Thanks to a recent consolidation of operations and a balance sheet strengthened by the conversion of debt to equity, the company has embarked on the major investments studied in their Business Plan to introduce new cutting-edge technologies and revamp existing equipment to support the targets of product sustainability and R&D for further growth stimulation in their key markets.

BIMO BOPP FILM ADVANTAGES BY VERTICAL INTEGRATION

BIMO BOPP FILM ADVANTAGES BY VERTICAL INTEGRATION

BIMO offers huge advantages – operating in a vertically integrated business model – which starts with the extrusion of BOPP films and continues with the printing and converting of finished products like labels, printed pack wraps and adhesive tape. BIMO offers a wide range of BOPP films in thicknesses from 14 to 70 micron all specially designed for the advanced industrial applications they serve. Three extrusion and stretching lines are installed – two of them with Tenter Sequential Stretching, and a third line using the innovative and flexible LISIM simultaneous orientation technology known as SOL, which allows frictionless film production with variable MD/TD stretching ratios, ideal for the production of special shrinkable films specifically designed for high performance wrapping lines like those used in the cigarette industry. The Tobacco Business Unit, inaugurated in 2002, is the specialist BU which manages the design, commercialization and production of the whole range of films dedicated to cigarette wrapping, based on the technical advantages offered by development with SOL technology, such as optical properties, shrinkage properties, and exceptional mechanical properties which deliver improvements in customer productivity and product appearance, even with cost-saving thicknesses as low as 16 micron. These products offer controlled and balanced shrinkage ratios, reliable low coefficient of friction, predictable sealing strengths, and exceptional transparency and gloss. The continuous development work over the past decade has built up a valuable knowledge base in BIMO which now offers films for all production circumstances, be they latest generation high speed packers or revamped older generation machines with or without single pack shrink tunnels, allowing the supplier to tailor his offering for each particular factory or wrapping line. The package is completed by bespoke and fast R&D on demand involving raw material suppliers, machinery manufacturers and research laboratories, and an expert team of applications technicians dedicated to sharing knowledge and best practice on all types of production lines in the customers’ factories.

Two years ago Bimo abandoned the commodity film business and strategically chose to focus all its resources on the core bespoke specialty businesses for multinational end-users and converters, a choice which has paid off handsomely already in the first two years in terms of margins, profitability and volume growth as the business model grows in reputation and successful implementation.