INTERPACK 2014

[twitter-follow screen_name=’itfoodonline’]

Tweet

Tweet #interpack 2014

For info please contact +39 0362 244182, or mail to info@itfoodonline.com.

STATE OF THE ART CUTTING TECHNOLOGY

STATE OF THE ART CUTTING TECHNOLOGY

We bring together experience and passion for the product.

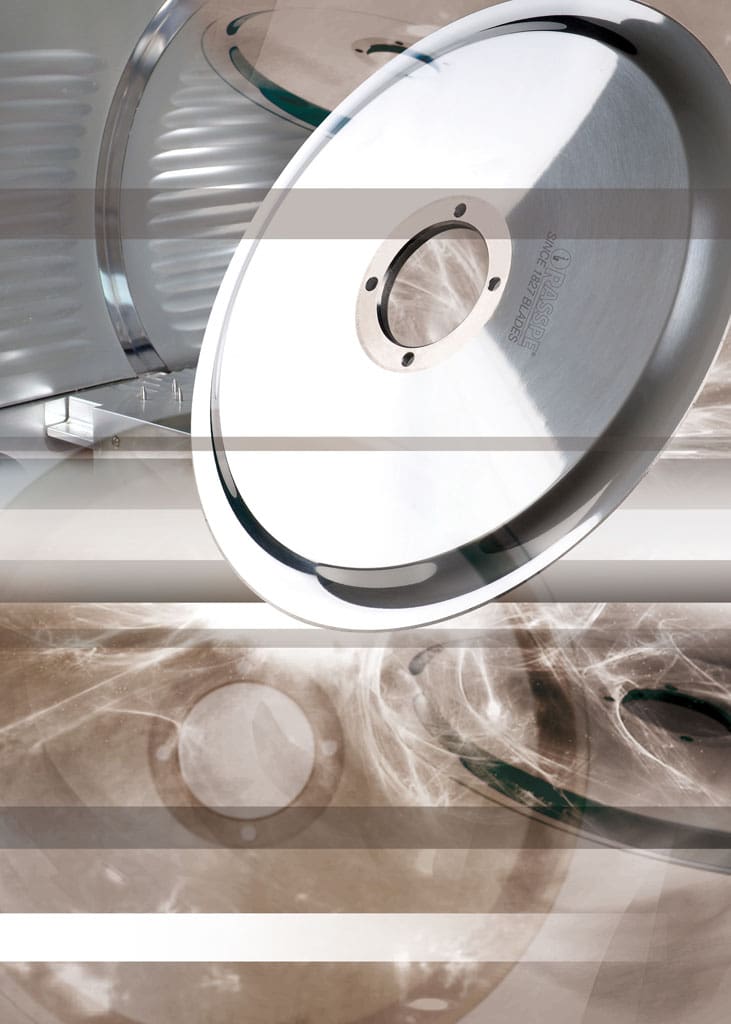

Chiaravalli Group S.p.A. is a leading company in the production of blades for slicing machines, with state of the art technology and a warehouse with over 250,000 finished parts, in order to satisfy immediately the needs of the customers.

Our company is the result of great passion and consistent investment of energies on entrepreneurial projects, for the creation of a wide range of extremely high quality products, able to meet the requirements of a market that is more and more demanding, and in constant evolution.

Our company is the result of great passion and consistent investment of energies on entrepreneurial projects, for the creation of a wide range of extremely high quality products, able to meet the requirements of a market that is more and more demanding, and in constant evolution.

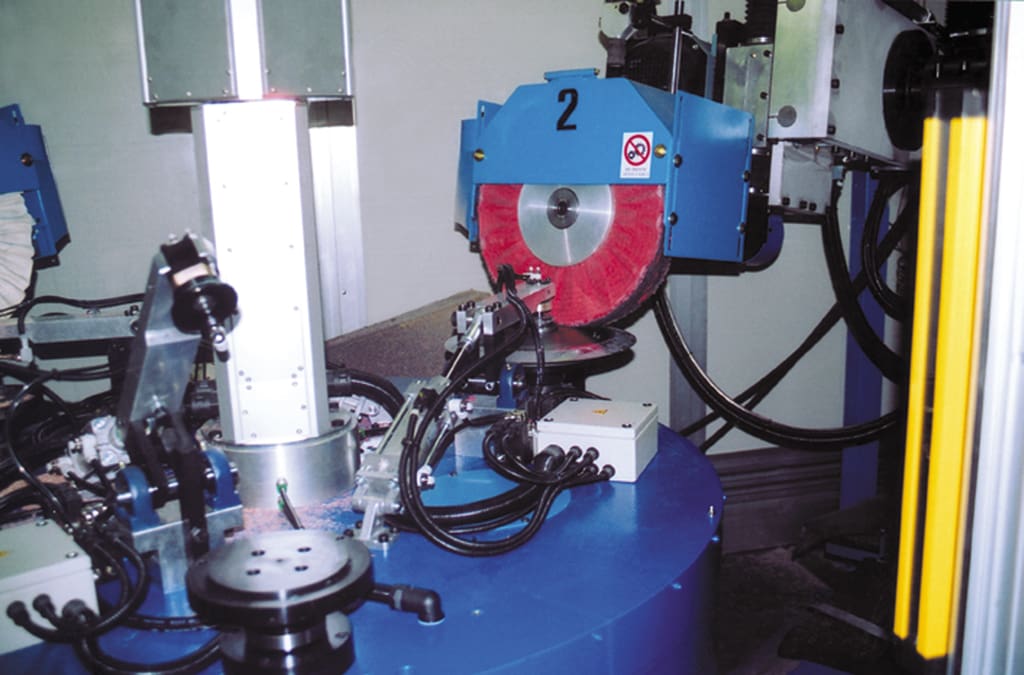

Chiaravalli Group S.p.A. brings together the great level of know-how of the historic German trademark RASSPE, consistently the most important manufacturer of blades for slicing machines for over a century, and the thirty year experience of their own personnel, together with the advanced technological features of the machines used to complete each production stage.

Chiaravalli Group S.p.A. brings together the great level of know-how of the historic German trademark RASSPE, consistently the most important manufacturer of blades for slicing machines for over a century, and the thirty year experience of their own personnel, together with the advanced technological features of the machines used to complete each production stage.

With our historic trademarks: RASSPE BLADES and KLINGER, we have been able to secure a strong presence in all the world markets.

THIRD GENERATION the new frontier of blades for slicing machines.

THIRD GENERATION the new frontier of blades for slicing machines.

Chiaravalli Group S.p.A. has introduced and patented a great innovation in the production of blades for slicing machines: the so-called THIRD GENERATION blades, conceived with the idea of a cut that is increasingly perfect, reducing waste to the minimum.

A profile structured on two different levels, and the narrow band, reduce the blade’s surface in contact with the product, avoiding pointless frictions, and ensuring that the part of the blade not directly involved in the cutting process is always cleaner.

This type of finishing can be applied to our whole range of items, and represents a winning solution for cutting cheese, cured meats and vegetables.

In summary:

• avoids the waste that is normal with traditional blades;

• enables to obtain extremely thin and perfect slices;

• the flavor of the product is unchanged because the blade does not become hot.

In addition, together with the traditional “MIRROR FINISH” that is characteristic of the highest quality standards, this development ensures:

• a further improvement in terms of cleanliness;

• high wear and abrasion resistance;

• high corrosion protection;

• low friction coefficient.