Handling and feeding are two key processes for inline food products packaging. Very widespread are in fact, food products packed in trays or pouches often accompanied by informational or promotional inserts that complement the packaging. Coupons, bulletins, leaflets, heat-sealed sachets for seasonings, and small gadgets are indeed very common additions included in a vast number of packages to meet multiple consumer communication needs.

When it comes to food packaging, Etipack offers a wide range of sturdy and reliable Feeder and Pick & Place machines capable of enduring the highest processing rates. Prominent among the top lines, are the Whizzy and Clippy Denester models, which, thanks to their flexibility and configuration options, can meet a broad set of production requirements.

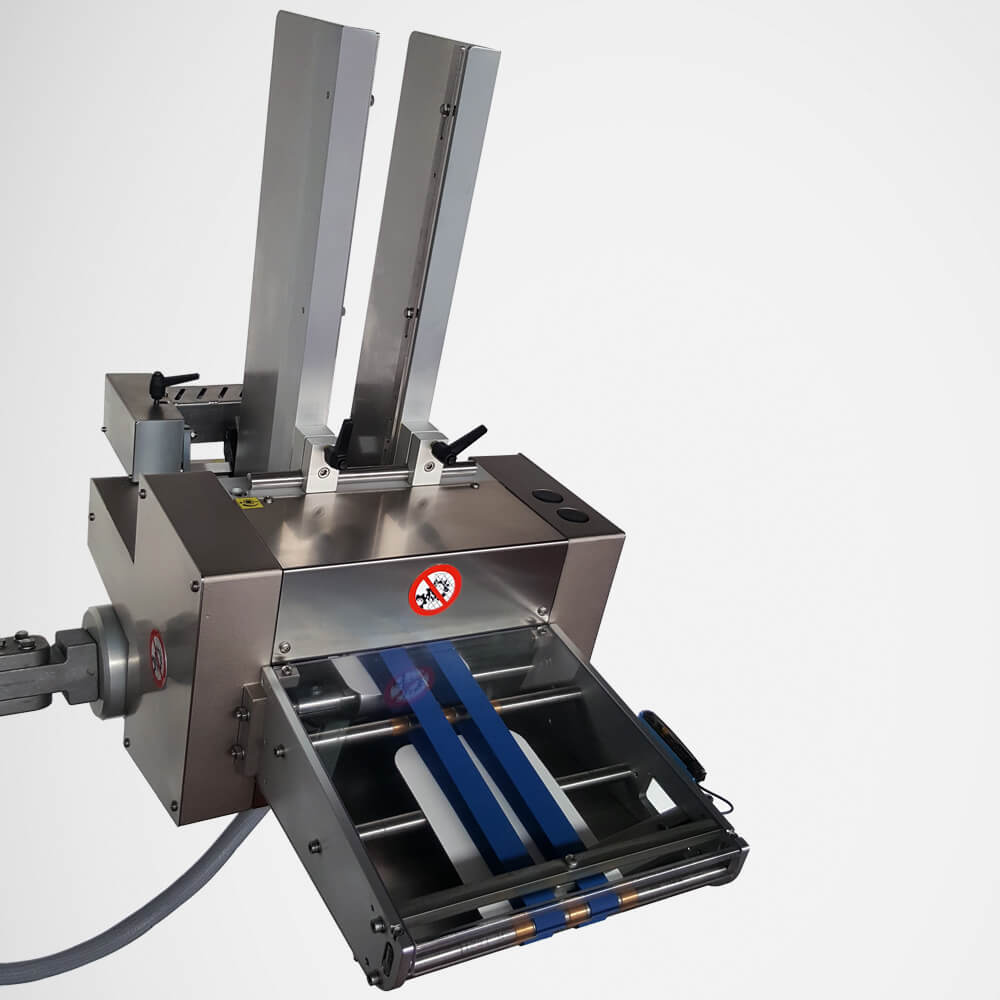

Whizzy is a machine for dispensing (friction singularization) and in-line distribution of flat and thin products that are precisely positioned in a defined space. Top of the range in the feeder family in terms of performance, accessories and possible formats, it is perfect for the integration into high-speed, high-precision production lines.

Among its many formats, Whizzy can accommodate, for example, coupons, coupons, bulletins, instruction sheets, pre-folded brochures, envelopes, promotional, folded, cards, and envelopes up to 3 mm thick, or 8 mm thick with special configuration.

It offers numerous configurations for horizontal or vertical processing, as well as the ability to handle formats of various sizes. It also features advanced management of data exchange with the machine and the line.

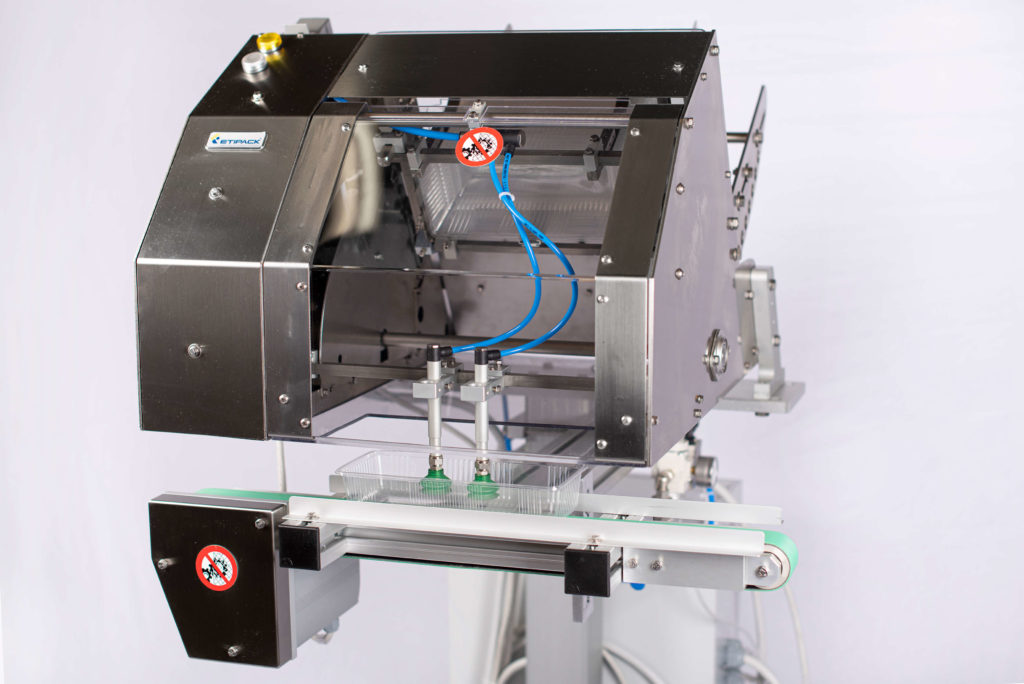

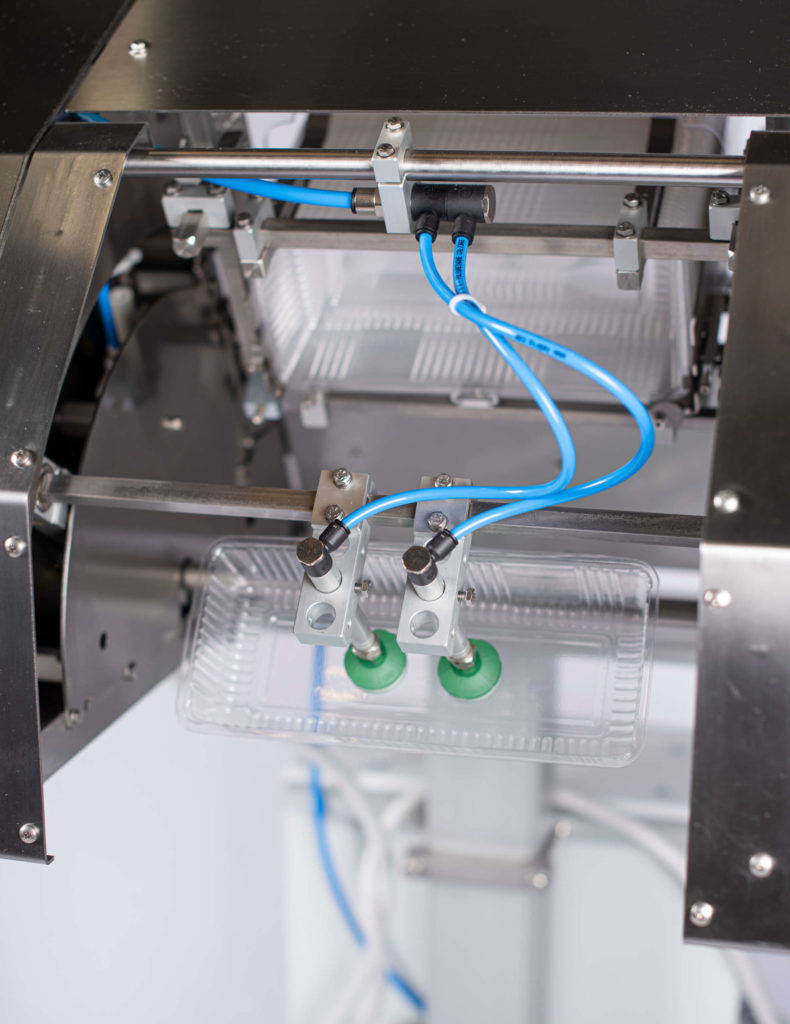

Clippy Denester is a de-stacker, i.e., a pick-and-place manipulator, for de-stacking thermoformed plastic trays and lids. By the use of suction cups, it picks up stacked products from a loading magazine, and distributes them horizontally down the packaging line.

It is equipped with a double loading magazine – to distribute 2 trays side by side and, thus, increase production speed -, as well as a programming keypad to set speed and control functions.

Interpack will hosts the most iconic Feeders and Pick & Place of the Etipack range

At Hall 8B booth C49, a solution representing the many possible configurations specifically dedicated to food trays packaging will be available at Interpack. The setup includes at the infeed, a Clippy Denester pickand-place de-stacker with double loading storage that allows, through the use of suction cups, to collect and distribute trays horizontally on the packaging line.

Afterwards, the package is conveyed to a Whizzy automatic friction feeder, complete with a loading storage unit, which dispenses flat and thin products complementary to the packaging, placing them with accuracy inside the tray. To complete the solution, a bottom labeling machine, which, as the package passes through, applies a label containing product information such as ingredient list, expiration date, batch, etc.

This configuration is emblematic of the many possible integration options offered by Etipack, which, alongside standard machines, combines tailor-made solutions designed according to specific and special requirements of both production companies and, above all, packaging line manufacturers who can count on solid design capacity and consolidated experience within the food sector.