Three brushless motor lines just perfect for the needs of the Food market

Mini Motor, the Italian company based in the heart of Emilia’s motor valley, has been designing and manufacturing electric motors for industry for over 55 years.

Present all over the world with operations in Europe, the USA and the United Arab Emirates and a widespread network of dealers, Mini Motor makes innovation and development their source of satisfaction.

Fast Change is here: Mini Motor creates a brushless line that ensures fast, effective and safe format changeover.

With the market increasingly moving towards packaging customisation and diversification and thus looking for a format changeover solution that is both reliable and fast, Mini Motor has listened and tapped into its expertise to come up with a new line of motors.

The Fast Change line stands out for features like compact size, high system compatibility and integration, remote control, and speed. Speed, in particular, is ensured by the greater motor running speed (twice as fast as our competitors) and the reduced downtime during format changeover, an operation that can be very costly in terms of time and productivity.

The electronics in FC lets you set parameters and run diagnostics remotely, enabling you to control and monitor the running status of the product and thus implement predictive maintenance, which is essential in order to service the machine within a short time frame.

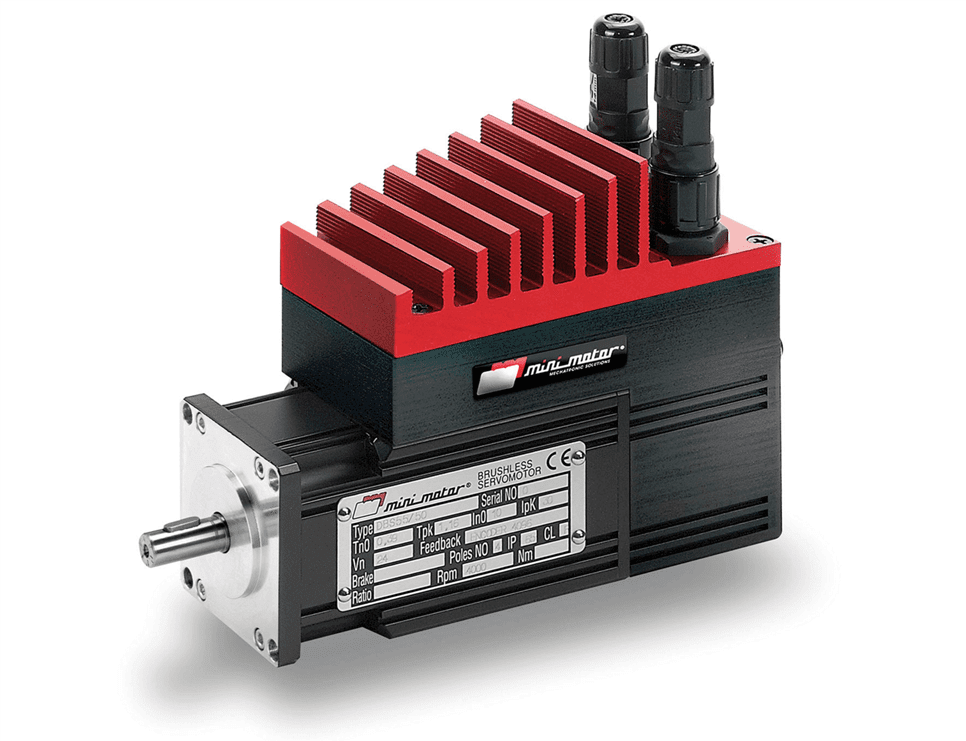

DBS Series

Up there with the top products we find the family of DBS brushless gear motors with built-in drive system where all the elements – motor, driver and reduction gear (where fitted) – are packaged in a single product of indisputable excellence.

The 4096-PPR multi-turn absolute encoder offers maximum freedom in terms of speed and position adjustment, maintaining the distance even when the motor is off. The great innovation about DBS is the presence of an accelerometer that is able to detect gear motor vibrations.

The accelerometer plus the other sensors that detect temperature, current and speed are able to identify anomalies within the sensors themselves or from the machine systems connected to them, implementing real predictive maintenance.

What’s more, with DBS several motors can be connected in a cascade system via the main communication protocols: EtherCAT, Ethernet/IP, Powerlink, Modbus, PROFINET I/O and CANOpen. The wireless protocol was recently added to these 6 fieldbuses.

Mini Motor has in fact patented the first all-wireless gear motor in the market powered by an inductive charging battery.

This means no drag chains, which translates into lower machine costs and greater freedom of movement.

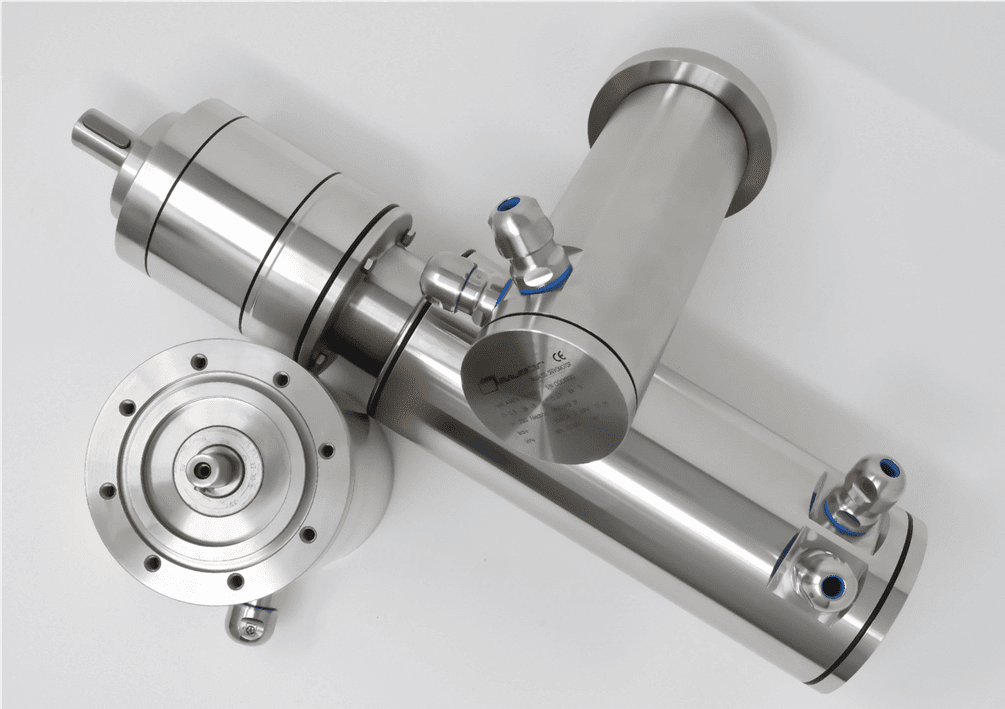

Offering full compliance with the strictest requirements of the industry, Mini Motor stainless steel motors guarantee the highest standards of hygiene, reliability and safety, your must-have allies in food processing and packaging.

Stainless steel is resistant to corrosion caused by foodstuffs and beverages, thus preventing their contamination and alteration. Thanks to this property, it was chosen as the star material for Mini Motor’s Clean brushless motors.

It is the top and unavoidable choice in the food industry because 316L stainless steel is extremely resistant to splashing boiling water (80°C) and high pressure (90 bar) plus very easy to clean.

Featuring a Hygienic Design, the series is ideal for use with the ageing systems used in pork and prosciutto processing plants, and with fish and seafood processing systems. These types of environments typically have high levels of salinity and the resistance of standard 304 stainless steel to corrosion is limited in such applications, whereas the 316L stainless steel chosen by Mini Motor is not affected.

The Emilia-based company does it again, not stopping at meeting what the market needs but tapping into its innovative side to go beyond and create products that deliver real improvements to companies and close the competition gap.