Energy-saving champion: IE5+ motors from NORD for food applications

Full efficiency and environmental awareness for food applications: The IE5+ motor generation from NORD DRIVESYSTEMS offers unventilated smooth motors in two sizes. The energy-saving motors were developed with a focus on the food industry and impress with their consistent high efficiency. They provide optimised performance and reduced total cost of ownership (TCO) thanks to corrosion resistance and hygienic design.

The most stringent hygiene requirements, absolute reliability and efficiency in use. Production processes in the food industry require maximum cleanliness and consume a lot of energy. Whether agitators, conveyor systems, dosing and filling systems or packaging lines: Machines place great demands on the drive technology in use. As one of the world’s leading full-range suppliers, NORD DRIVESYSTEMS is highly familiar with the requirements of the industry, developing and producing scalable drive solutions. NORD also designed its latest IE5+ motors for the food processing industry.

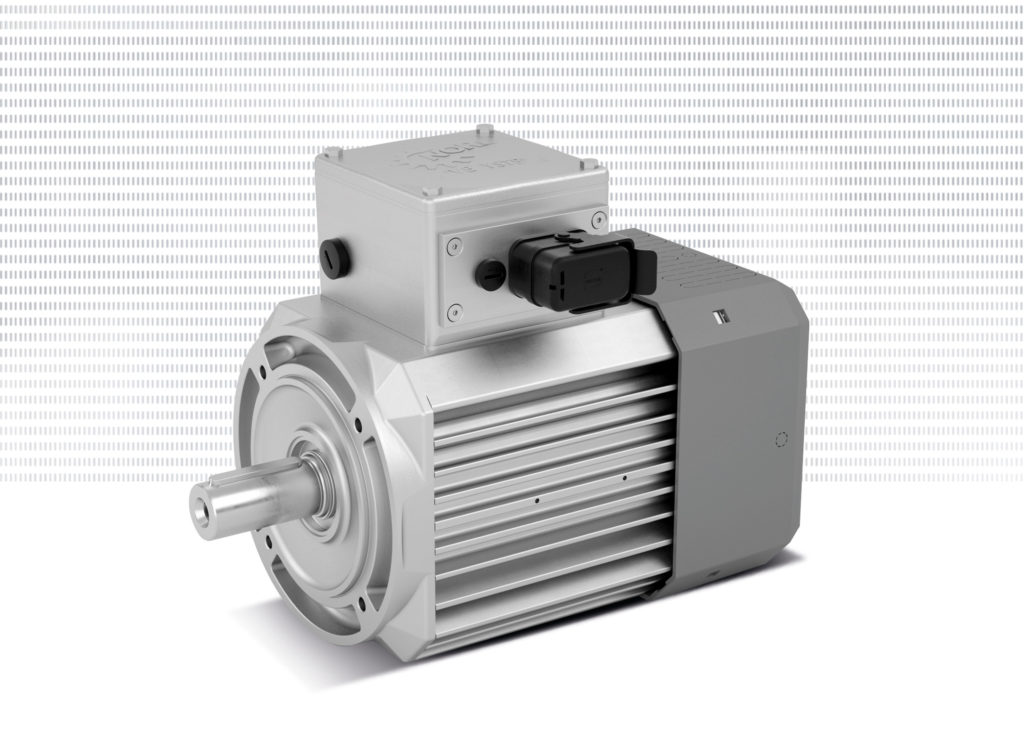

Compact motor without fan

Compared to the current IE4 series, the energy-efficient permanent synchronous motor considerably reduces losses and achieves an efficiency that is significantly above efficiency class IE5. The unventilated smooth surfaced motor achieves its high efficiency over a wide torque range, making it optimally suitable for economic operation in the partial load and speed range. Thanks to its hygienic design, it is easy to clean. The smooth surfaces reduce soiling and are easy to clean. Since the compact IE5+ motors do not require a fan, they prevent the spread of germs while ensuring smooth running. In addition, the new motor series offers high corrosion resistance, high reliability and a long service life. Frequency inverters can be installed very flexibly, either integrated into the motor or close to it.

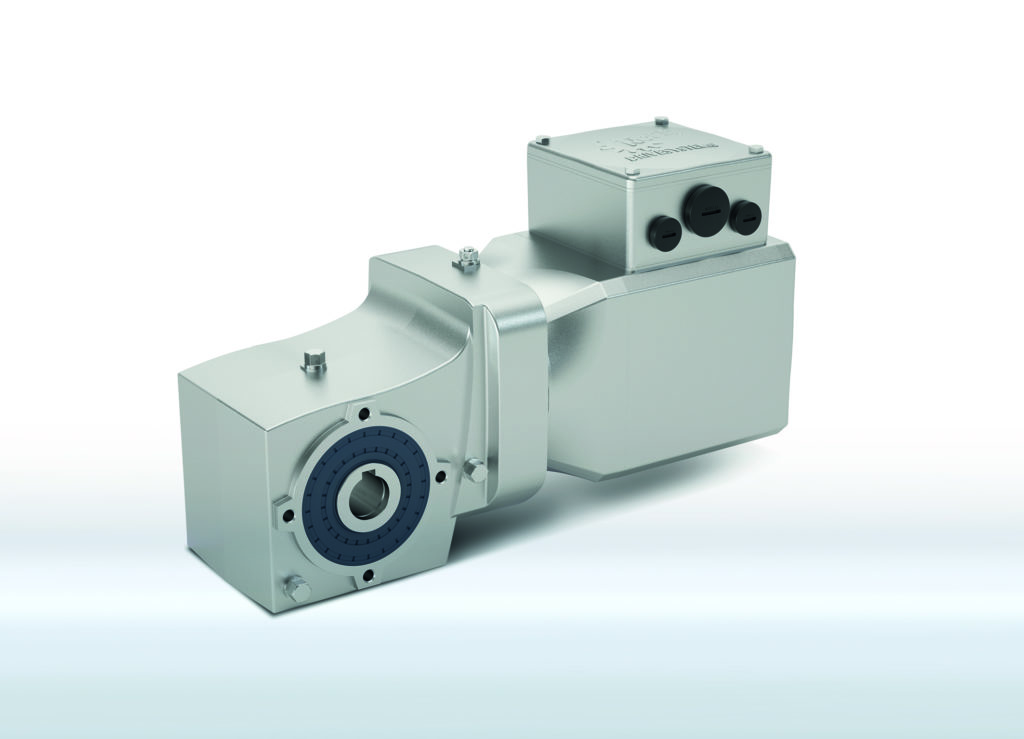

nsd tupH as an alternative to paint

Aluminium offers a certain degree of corrosion protection by nature. When used in harsh environments or when cleaning agents are involved, the nsd tupH surface treatment can be applied to the IE5+ motors. Thanks to a special method based on an electrolytic process, the surface is made harder and resistant to corrosion. This way, aluminium becomes similarly corrosion-resistant to stainless steel. In contrast to painting or coating, nothing can detach or flake off. Damage remains locally restricted and does not spread. The surface is easy to clean and largely resistant to acids and alkalis. Even the use of high-pressure cleaners common in the food and beverage sector or contact with aggressive media is possible.

nsd tupH drives are therefore a robust and durable alternative to painted cast iron geared motors or even stainless steel versions, and are also cheaper than stainless steel motors. For nsd tupH versions, all DIN and standard components, including output shafts, are made from stainless steel as a standard. Drive systems from NORD with nsd tupH comply with FDA Title 21 CFR 175.300 and are therefore suitable for food applications.

Well-known NORD flexibility

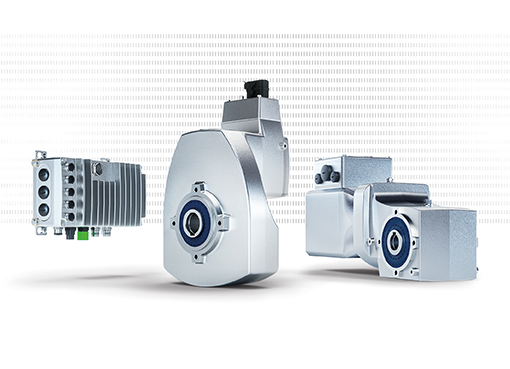

A large number of processes are necessary before a finished product arrives on the plate or in the glass. The number of drives used is correspondingly high. Due to constant torque over a wide speed range, new IE5+ motors allow a targeted reduction of versions. In this context, a version is a combination of gear unit, motor and frequency inverter available in different sizes and gear ratios. The output speed can be adjusted over a wide range using a suitable NORD frequency inverter. If this property is combined with the good overload capacity of the IE5+ motors, only a single motor type can be used instead of various motor sizes. Dependent on the performance requirement, its inverter operates it with different frequencies. The solution will be tailored to each customer and specifically designed for the system’s individual load range.

Compact installation space paired with high power density

With the new generation of IE5+ motors, NORD DRIVESYSTEMS takes the step towards a new product system landscape with focus on ultimate energy efficiency paired with compact design. The size 71 synchronous motor is suitable for the power range from 0.35 to 1.1 kW with a continuous torque from 1.6 to 4.8 Nm and speeds from 0 to 2,100 rpm. Size 90 is suitable for the power range from 1.1 to 2.2 kW with a continuous torque from 6.8 to 10 Nm. Both direct motor attachment as well as NEMA and IEC motor attachments are available. An integrated encoder is part of the standard equipment. Optionally, an integrated mechanical brake and protection class IP69K are available.

Due to the optimised power density, space savings of up to 40% can be achieved with the new IE5+ motor compared to conventional asynchronous motors. That means: The same installation space can accommodate a more powerful motor with higher energy efficiency. Due to an efficient use of materials and a compact size, the IE5+ synchronous motor has a weight advantage of more than 50% compared to IE3 asynchronous motors within the same power range.

Another plus for conveyor systems and handling machines in food processing and beverage production: Thanks to its low moment of inertia, the motor has a high dynamic starting and acceleration performance. The motor’s inertia can be reduced by 50% compared to previous IE4 permanent magnet synchronous motors, and by 80% compared to standard IE3 asynchronous motors. They allow for shorter ramp times or more dynamic applications with a positive effect on throughput times.

Conclusion:

Hygienic, efficient and compact: The new IE5+ synchronous motor sets standards in power density, reliability and economy, providing considerable performance advantages in terms of production, processing, filling and packaging of food and beverages. Thanks to IE5 technology, the motor ensures ultimate efficiency as well as operational safety and makes a significant contribution to reducing the total cost of ownership (TCO). Thanks to its design and the operation with the frequency inverter, the same motor variant can be universally used worldwide. This means that the same motor type can be used independent of the respective mains voltage or local energy efficiency regulations. The new IE5+ motor can be combined with all gear units and drive electronics from NORD DRIVESYSTEMS in a modular system.