Modular and Compact labelling systems for front and back application onto cylindrical products

Thanks to the countless labelling solutions already developed by LABELPACK, designed for the application of one or more labels onto cylindrical products, managing the in-line printing of variable data and barcodes, the company is able to face and solve many identification and customisation issues.

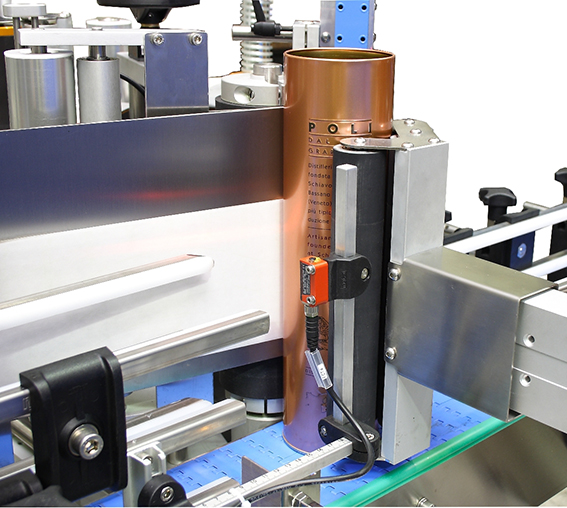

One of the most requested solutions is the labelling system for front and back application onto cylindrical, oval and rectangular products, which also includes the possibility of applying a warranty label. All these applications are now possible thanks to the MODULAR and COMPACT systems.

The highest technological solution is realised with the MODULAR system, an “open frame” modular structure made in stainless steel featuring several automatic labelling systems for top and bottom application. The system consists of a centralised electronic control panel placed on a balcony structure with PLC and Touch Screen operator panel. Moreover, the speed functioning can be electronically synchronized and the fast regulations with numerical indicators facilitate the format change and the following repositioning to previous position. The MODULAR automatic labelling systems have different conveying equipments according to the dimensions, weight and shape of the relevant container. The conveying systems are placed on the balcony structure making them easy to clean and avoiding spillage onto remote parts of the machine that can be difficult to reach and clean.

LABELX labelling units operate with a maximum label width of 140-250mm and can integrate the units designed by MARKEM, VIDEOJET, SAVEMA, ALLEN, etc… for the in-line printing of variable data, barcodes and other relevant information.

COMPACT labelling systems are the “entry level” series including 8 standard models and several customised solutions. They are equipped with LABELX JR labellers, which operate with a maximum label length of 350mm and maximum label height of 140/250mm. COMPACT TS, COMPACT TB and COMPACT BS are the labelling systems for top and bottom applications onto trays, cases, boxes, flow-packs and bags. The conveying systems are available in different models (flat belt, plastic chains, stainless steel chains) and can be customised in length and width according to the dimensions of the product and the requirements of the packaging production line.

All COMPACT labelling systems can be equipped with one or more thermal transfer printing units of variable data, barcodes and other relevant information. To complete the labelling system other accessories and options are available: sensors for transparent labels, product spacers and stabilisers, rotary tables for inline loading and accumulation.

LABELX and LABELX JR automatic labelling systems complete LABELPACK offer for the beverage sector. LABELX has proved to be the most appreciated solution, able to face many labelling issues. LABELPACK has already produced thousands of LABELX machines. It is a high-performance and reliable labeller, which disposes of a big range of accessories that ease the installation onto any automatic packaging line and it is available in three different width: 140mm, 250mm and 350mm. Its high technology guarantees the best performance at high speed and with great application precision. The simple and functional Touch Screen operator panel allows managing all operations.

LABELX is also available in a RM version with motorized re-winder, suitable for high speed application – it can reach an application speed of 80 m/min. This model is equipped with a 400mm diameter mechanical unwinder.

LABELX JR complete the LABELPACK offer – it is an automatic labeller for medium and low speed application, which can be equipped with thermal transfer printing units of variable data and barcodes.

LABELPACK offer a wide range of print & apply solutions ideal to be integrated onto end of packing line and palletization systems. With the PandA and PandA JR systems it is possible to solve many application and printing issues onto bottle boxes of barcodes and variable data on a self-adhesive labels to be then automatically applied on the product to identify. PandA MASTER is the top-quality solution to apply & print the identification labels for pallet with Serial Shipping Container Codes (SSCC).

Thanks to its integral protection PandA MASTER can work in any particular environmental conditions and can apply labels onto one or two sides of a pallet. PandA machines are guaranteed by integrating industrial thermal transfer print units made by major international companies, such as DATAMAX, ZEBRA, SATO, NOVEXX-AVERY, CAB, CARL VAENTIN and are controlled by the BarTender software, which is very easy to connect to any management system and control system of the production lines.

www.labelpack.it