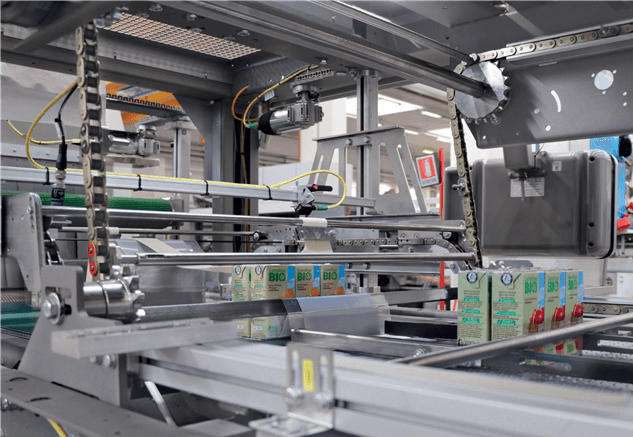

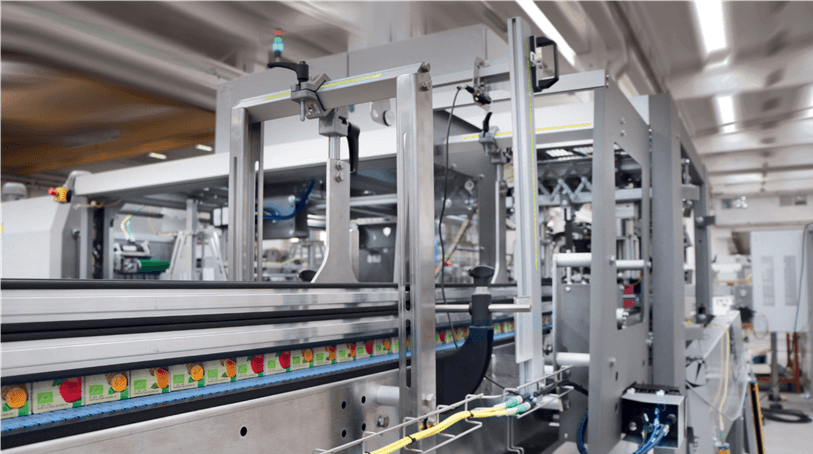

Among the numerous innovations made to its product portfolio, SMI has decided to expand the ASW ERGON series of compact packaging machines for shrink film packaging with single lane infeed and 90° product introduction.

The range of this type of machines, has in fact been enriched with 6 new models, dedicated to the packaging of a wide range of containers with a cylindrical, oval or square / rectangular base at the maximum speed of 30 (ASW 30) and 40 (ASW 40) packs per minute.

The ASW ERGON series was designed two years ago, from the desire to offer a compact version with single lane infeed, suitable for production needs from 50 to 80 packs per minute, of the “historic” range of SK series automatic packaging machines, marketed by SMI with great success since the mid-nineties.

The favorable market reception of the ASW 50, 60 and 80 has led SMI to extend the range of these machines also to those who need lower speeds, introducing the new ASW 30 and ASW 40 ERGON models.

The latter combine the best of the SK ERGON series with some innovative technical solutions present on the models of the LSK ERGON series in terms of modular assembly, space saving, process simplification, advanced ergonomics and latest generation automation.

The various models of the ASW ERGON series allow packaging in shrink film only, in pad + film and in tray + film.

New models of compact shrinkwrappers with 90° infeed

The ASW packaging machines, equipped with a single- lane infeed belt, have the considerable advantage, also in economic terms, of not requiring the presence of a divider for channeling loose products; moreover, the format change operations are completed quickly and in a simplified manner, because it is possible to process different types of containers, of various sizes, without having to resort to additional equipment.

This compact solution easily adapts to the logistical conditions of the end of line of any production plant; in fact, in the infeed section, the ASW ERGON SMI packaging machines, are equipped with a single lane infeed system, preferably positioned on the side opposite the operator, which facilitates the correct channeling of loose containers on a conveyor belt equipped with low friction thermoplastic chains.

In the pack formation area, a pneumatic device groups the containers alternately, before the packaging operation, in the desired configuration; this section is characterized by a double belt system, which, through an electronic cam, separates the products according to the format to be processed. Subsequently, thanks to the rotary feeder, the loose products are moved from the single lane conveyor to the multi-way conveyor belt at the machine infeed.

In the ASW P and T models, the carton magazine is located under the infeed belt; from here the corrugated cardboard pads or trays, taken by means of an alternating motion picker equipped with a group of suction cups with pneumatic suction system, run along the cardboard ramp and are positioned under the group of incoming products with the wide side facing forwards.

The unwinding of the film reels, positioned in the lower part of the machine, is controlled by a progressive brake, which ensures optimal film tensioning. The splicing of the film at the end of the reel, takes place via a manual sealing bar.

The reel-holder spindles have pneumatic locking and when the reel film is running out, a special device intervenes to stop the machine. Before the pack enters the shrink tunnel, the film is cut by a motorized blade knife, wrapped around the group of containers and superimposed on the bottom of the pack.

ASW 30/40

• Single lane infeed

• 90°product introduction

• Compact structure Rapid simplified format changeover

• Easier maintenance

• Film unwinding controlled by progressive brake, which ensures constant and optimal film tensioning

• Automatic setting of film winder

• Posyc® control panel with 7” colour touch screen