Omag is an Italian company that has been designing and manufacturing packaging machines for powdery, granular, liquid and pasty products in 3 and 4 side sealed sachets, stick-packs and doy-packs for over 45 years. Omag was founded in 1973 and today counts over 120 employees and its export business accounts for 70% of the turnover.

The company has three production plants: one entirely dedicated to the production of components (about 65% is produced internally) and the new headquarters of over 6000 square meters where mechanical and electronic design, machinery assembly and testing take place.

International sales network and, thanks to agents and distributors, a global presence, which is also supported by two foreign sales offices in Russia and Ukraine, directly managed by founding partners.

Our Product

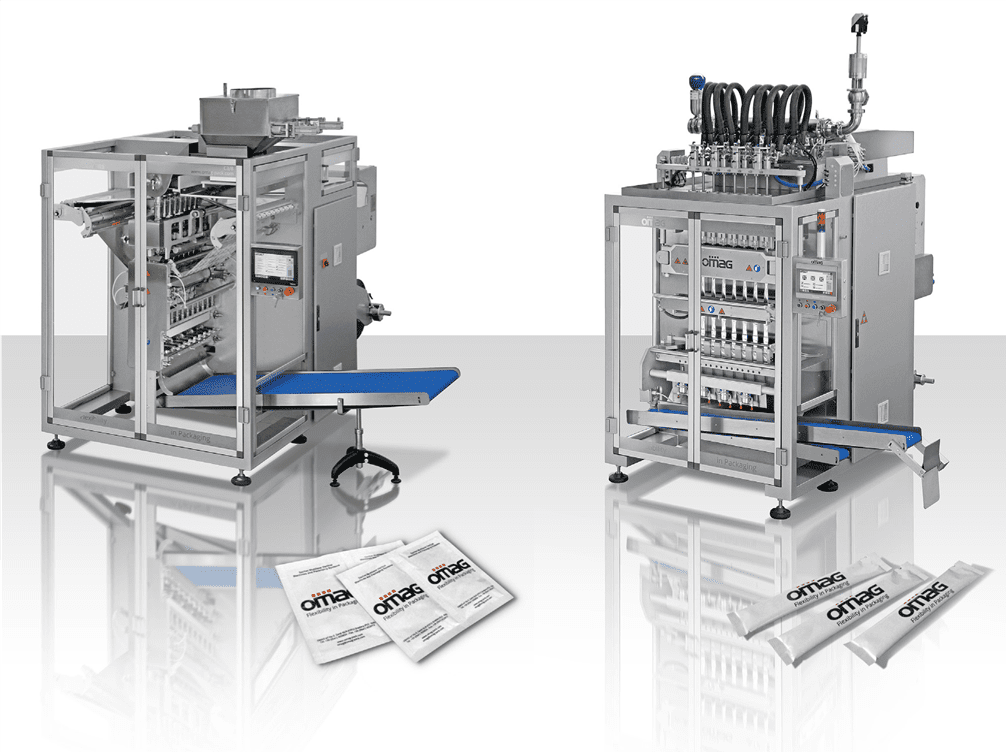

All Omag sachet and stick packaging machines can be manufactured on a variable number of rows, equipped with different dosing systems, combined with robotic counting units and cartoning machines and can be completed with different options such as batch number and expiry date printing, check weighers, etc.

Our main characteristics are certainly quality, sturdiness, design and reliability and they can be found in all our packaging machines, but the key attribute that set us apart is the flexibility.

In our business there are no machines built in series: each machine is designed ad hoc, tailor-made according to customer’s objectives and requests.

At the base there are highly technological machines able to meet our customers ‘needs, also through robotized systems and each machine is different from the other. This is flexibility as we understand it, which, combined with passion and the desire to push ourselves higher and higher, has allowed us to get where we are today.

Customer centricity

We do what we do best: we design and build high quality, high-tech machines with an essential design to ensure easy operation. We pay great attention to our customers’ needs, in fact it is fundamental for us to fully satisfy them not only during the sale phase but especially after the installation of the packaging machine.

A well-structured aftersales office allows a prompt assistance to the customer also through on-site and remote interventions, training and training activities. We offer customer service and create a relationship of mutual trust that brings value to both.

We also support our customers in the pharmaceutical sector with the drafting of highly professional GAMP5 documentation packages that simplify the validation process of our machines.

Innovation and Industry 4.0

From a technological point of view, in recent years we have focused on issues related to the opportunities offered by industry 4.0 and energy saving. In fact, all our models are now offered in a fully electronic version, guaranteeing flexibility and energy saving.

As far as industry 4.0 technologies are concerned, we use a series of software implemented on our packaging machines to comply with regulations in terms of traceability, safety, quality and interconnection with company information systems.

In addition, thanks to remote control, our customers can request additional services that allow us to monitor and interact with packaging machines installed worldwide with real-time access to a series of functional data to diagnose their status and provide targeted assistance in case of anomalies.

With the aim of ensuring increasingly timely service, we are developing artificial intelligence algorithms for predictive maintenance, i.e. the prevention of potential faults before they occur in order to avoid unexpected production downtime.

We have also integrated augmented reality systems so that the customer, by framing the packaging machine with a smart device, can have immediate access to a series of data, user and maintenance manuals and analyze the status of the machine in complete autonomy.