The new melon and pineapple peeler mod. PL4D was born: doubled production capacity, reliability as our core value.

PND srl is continuing to work side by side to their customers answering to all their requests actively and carefully. In this way the new melon and pineapple peeler and corer mod. PL4D was born, always manually fed and works for outer peeling all fruits, even if they are not calibrated or have an irregular shape. They can thus be easily peeled with maximum efficiency. To increase the production, the new system allows the peeling on two heads while the other two are loaded. Besides, as per the models in the market, the machine is equipped with an ejector that discharges the fruit directly unto the belt, so to make the processing easier and have a better hygiene and fruit maintenance. The machine has a stainless steel structure. All components are easily changeable; all parts in touch with the fruit are made in food-approved material. The machine is provided with an electrical board equipped with two inverters: one to adjust the fruit speed and the other one to adjust blade speed. The peeler PL4D is equipped with two belts, one for peeled fruit and the other one for waste.

PND srl is continuing to work side by side to their customers answering to all their requests actively and carefully. In this way the new melon and pineapple peeler and corer mod. PL4D was born, always manually fed and works for outer peeling all fruits, even if they are not calibrated or have an irregular shape. They can thus be easily peeled with maximum efficiency. To increase the production, the new system allows the peeling on two heads while the other two are loaded. Besides, as per the models in the market, the machine is equipped with an ejector that discharges the fruit directly unto the belt, so to make the processing easier and have a better hygiene and fruit maintenance. The machine has a stainless steel structure. All components are easily changeable; all parts in touch with the fruit are made in food-approved material. The machine is provided with an electrical board equipped with two inverters: one to adjust the fruit speed and the other one to adjust blade speed. The peeler PL4D is equipped with two belts, one for peeled fruit and the other one for waste.

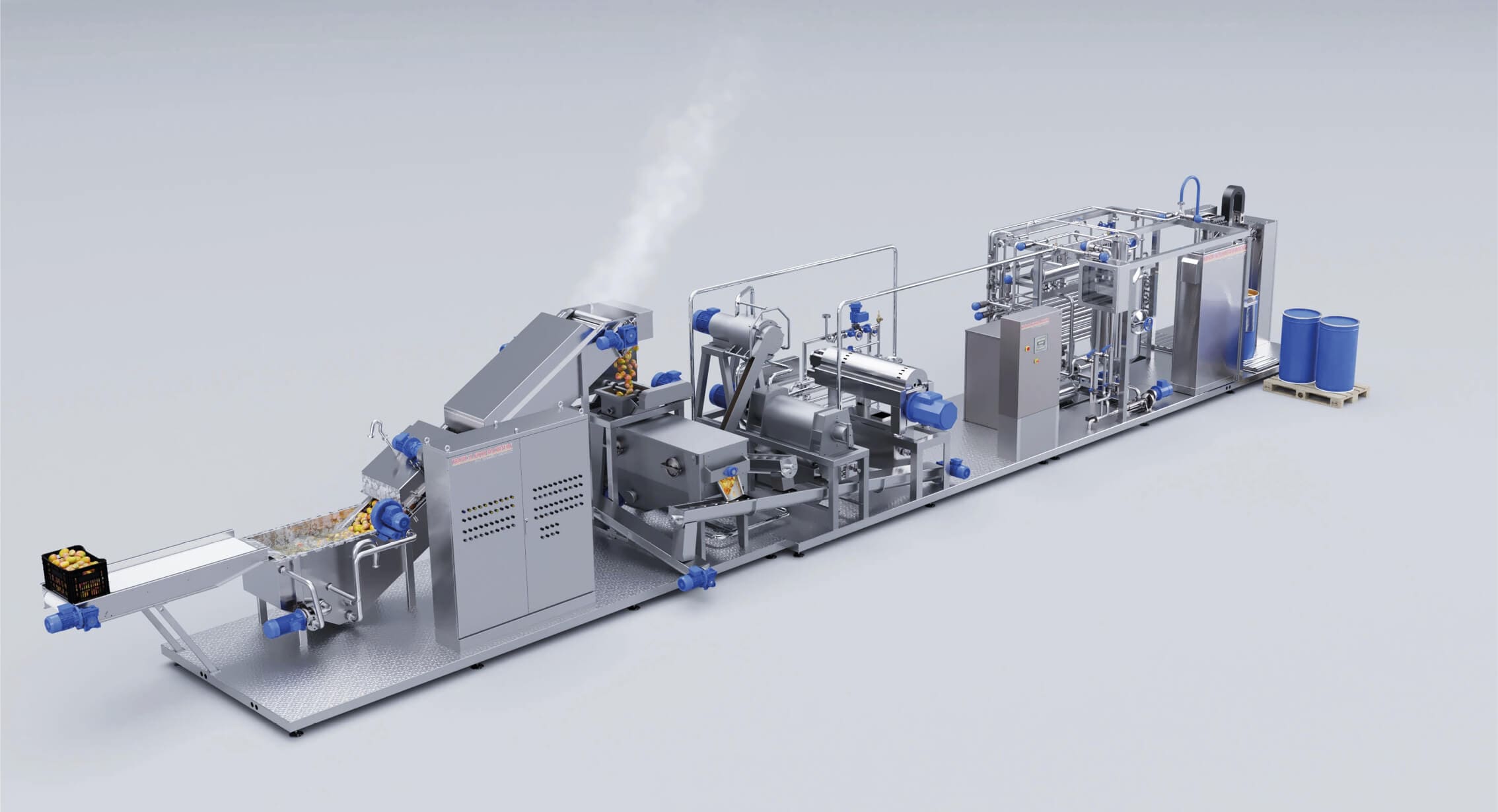

PND offers a wide range of products including peeling, coring and cutting machines for apples, pears, kiwi, oranges, pineapples, melons, watermelons, mangos with manual or automatic feeder, prewashing tank and treatment tank. The company also offers complete automatic lines for the canning industries and manual lines for fresh-cut fruit, for small laboratories and processors who want to start this business in fruit processing. One of the bestselling machines has been the semiautomatic peeling, coring and cutting machine for apples, pears and kiwis. This machine has production capacity from 20 to 80 fruits per minute, depending on customer specifications. With different optional equipment, this highly versatile machine can cut wedges and chunks.

PND offers a wide range of products including peeling, coring and cutting machines for apples, pears, kiwi, oranges, pineapples, melons, watermelons, mangos with manual or automatic feeder, prewashing tank and treatment tank. The company also offers complete automatic lines for the canning industries and manual lines for fresh-cut fruit, for small laboratories and processors who want to start this business in fruit processing. One of the bestselling machines has been the semiautomatic peeling, coring and cutting machine for apples, pears and kiwis. This machine has production capacity from 20 to 80 fruits per minute, depending on customer specifications. With different optional equipment, this highly versatile machine can cut wedges and chunks.

This kind of peeler in models PL4/PL6/PL8 can be automated thanks to the automatic feeder and orientator for apples, making the complete automatic line for apples processing. Wholly constructed from stainless steel, the machine is easy to clean and sanitize and allows for a fast maintenance. When connected to the automatic feeder for Williams pears, customers can enjoy a fully automated pear processing line. The automatic pears feeders is also fully constructed from stainless steel 304 and the entire structure is positioned on a sliding carriage which allows for easy maintenance and adjustment of the peeler.

Working closely to their customers has enabled PND to share their experience and knowledge and to continuously innovate. PND is backed by a team of professional highly skilled technicians and engineers who offer their support from the initial contact, to the installation, start-up and personnel training. PND’s flexibility and expertise guarantee solutions that are tailored to each customer. Further strengthening their capabilities is PND’s commercial network of representative offices. This allows PND to maintain a high level of contact with their customers anywhere in the world providing the capability to quickly and efficiently solve any issues related to installation, maintenance and troubleshooting and spare parts. The company has more than 500 machines successfully placed in Europe, South America, United States, Asia and Australia.

Working closely to their customers has enabled PND to share their experience and knowledge and to continuously innovate. PND is backed by a team of professional highly skilled technicians and engineers who offer their support from the initial contact, to the installation, start-up and personnel training. PND’s flexibility and expertise guarantee solutions that are tailored to each customer. Further strengthening their capabilities is PND’s commercial network of representative offices. This allows PND to maintain a high level of contact with their customers anywhere in the world providing the capability to quickly and efficiently solve any issues related to installation, maintenance and troubleshooting and spare parts. The company has more than 500 machines successfully placed in Europe, South America, United States, Asia and Australia.

New patent for STRAWBERRY DE-CALYX MACHINE Mod. DF24: PND is proud to introduce in the market this new patent machine developed to remove the strawberry calyx (top green cap with leaves) and, if desired, cut strawberries in half or four pieces. Low waste at 8-10% guaranteed, labor saving, high capacity, easy maintenance and sanitation. Double capacity respect to the Model DF12, less consumption. Ask us more details writing to info@pndsrl.it!!