A new concept for ice cream making machines: Ideatre

Carpigiani, a company specialized in the manufacturing of ice cream making machines, is now associated with the concept of “Italian style” ice cream. The constant innovation has made the company a technology leader – a large percentage of Carpigiani’s turnover is continually reinvested in research, design, selection of high-quality components, equipment safety and promotion of a balanced diet. The company aims at providing its customers with machines that are easy to use, solid and extremely hygienic, while guaranteeing lower operational costs and high investment returns. Recently, Carpigiani’s innovations focused on the manufacturing of a machine capable to drastically change the food retail market. The aim was to come out with a unique solution for the production, the storage and the display of ice cream as well as other pastry products. The results of this endeavour was IdeaTre: a machine that can be well displayed in a shop thanks to its linear style, which allows the customers to watch the ice cream making process right where it is served. The product is in fact stored in the same container where it is made.

Carpigiani, a company specialized in the manufacturing of ice cream making machines, is now associated with the concept of “Italian style” ice cream. The constant innovation has made the company a technology leader – a large percentage of Carpigiani’s turnover is continually reinvested in research, design, selection of high-quality components, equipment safety and promotion of a balanced diet. The company aims at providing its customers with machines that are easy to use, solid and extremely hygienic, while guaranteeing lower operational costs and high investment returns. Recently, Carpigiani’s innovations focused on the manufacturing of a machine capable to drastically change the food retail market. The aim was to come out with a unique solution for the production, the storage and the display of ice cream as well as other pastry products. The results of this endeavour was IdeaTre: a machine that can be well displayed in a shop thanks to its linear style, which allows the customers to watch the ice cream making process right where it is served. The product is in fact stored in the same container where it is made.

SEW automation: a mechatronic proposal

The collaboration with SEW Eurodrive responded to the need to comply with the machine operational requirements. In particular, it was necessary to find a solution capable to activate the beaters, to modulate their speed according to the recipe and to provide a double current feedback which could monitor the texture of the ice cream. An engine, a reducer and a drive had to be integrated in only one component. The great challenge was to comply with these requirements while containing the energy cost and reducing the amount of space of the machine (the smallest solution was to be contained within a square meter). The MOVIEGEAR® DSC drive system is a top quality mechatronic decentralized system. It is an intelligent device with a unique conception of the control part. It integrates a IE4 motor, a reducer and a high efficiency drive. MOVIEGEAR® DSC net communication features reduce the start-up time, facilitating problems detections and maintenance. The low noise emission of MOVIGEAR® DSC allows utilizing the machine everywhere.

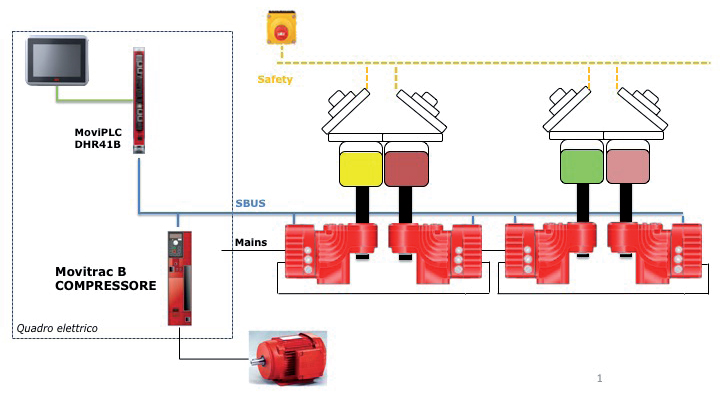

The collaboration with SEW Eurodrive responded to the need to comply with the machine operational requirements. In particular, it was necessary to find a solution capable to activate the beaters, to modulate their speed according to the recipe and to provide a double current feedback which could monitor the texture of the ice cream. An engine, a reducer and a drive had to be integrated in only one component. The great challenge was to comply with these requirements while containing the energy cost and reducing the amount of space of the machine (the smallest solution was to be contained within a square meter). The MOVIEGEAR® DSC drive system is a top quality mechatronic decentralized system. It is an intelligent device with a unique conception of the control part. It integrates a IE4 motor, a reducer and a high efficiency drive. MOVIEGEAR® DSC net communication features reduce the start-up time, facilitating problems detections and maintenance. The low noise emission of MOVIGEAR® DSC allows utilizing the machine everywhere.

According to the end user’s requirements, from 4 to 16 Movigear® DSC systems can be installed on IdeaTre. These are handled by a single MOVI-PLC®Advanced controller, which recognizes the number of devices connected to the net and configures them automatically. Thanks to a communication protocol in Modbus, the MOVI-PLC® communicates with the operator panel for managing the recipes and the machine control. A further advantage of the machine lies in its extreme ease of wiring, due to the daisy chain technology that minimizes the amount of space required by electric wiring and fieldbus devices. Thanks to the IE4 high-efficiency technology and to the high-performance gear unit, it is also possible to produce ice-cream in a sustainable way, with a potential 20% energy saving. During the last SPS trade fair, IdeaTre was presented within the SewEurodrive stand to show how to successfully use MOVIGEAR® DSC.

According to the end user’s requirements, from 4 to 16 Movigear® DSC systems can be installed on IdeaTre. These are handled by a single MOVI-PLC®Advanced controller, which recognizes the number of devices connected to the net and configures them automatically. Thanks to a communication protocol in Modbus, the MOVI-PLC® communicates with the operator panel for managing the recipes and the machine control. A further advantage of the machine lies in its extreme ease of wiring, due to the daisy chain technology that minimizes the amount of space required by electric wiring and fieldbus devices. Thanks to the IE4 high-efficiency technology and to the high-performance gear unit, it is also possible to produce ice-cream in a sustainable way, with a potential 20% energy saving. During the last SPS trade fair, IdeaTre was presented within the SewEurodrive stand to show how to successfully use MOVIGEAR® DSC.

THE 85th BIRTHDAY OF SEW-EURODRIVE

2016 marks the 85th year since the constitution of SEW-EURODRIVE. Born as a small 16-employees laboratory, the company grew until it has become a world leader in the fields of industrial, logistic and processing automation. SEW-EURODRIVE is a synonym of movement, tradition, innovation, quality and commitment: it has been proving it to its customers every day for the last 85 years. Every day, 550 researchers and designers create the future automation solutions. All over the world, more than 16,000 collaborators are in motion to satisfy the customers’ needs and optimize their processes. The company is present in Italy since 1969 with the Drive Technology Centre in Solaro, near Milano, where the management offices, the Operational Centre and the Customers Services are based. The Drive Centres located in Turin, Bologna, Verona, Caserta and the Sales Office in Pescara guarantee a widespread presence on the national territory, committed to the motto “Think global, act local”.