Labelling and distribution of vacuum-packed products: the Etipack project for SMOKED SALMON

Managing the distribution and labeling of vacuum sealed plastic bags of salmon with the utmost precision and control, was the goal of a company specialized in processing and retailing smoked, marinated and flavored salmon, as well as other smoked fish varieties.

The challenge was to create a solution that would be able to distribute, handle and label products, guaranteeing accurate control of overprinted variable data and the rejection of non-conforming packs. From a handling point of view, the system required by the customer had to optimize effectively and quickly the loading and transport of as many packs as possible.

With regard to data management, the need was instead, to have maximum autonomy and flexibility, on one hand, in the design of the label, and on the other in variable data input, printing, management and control.

Finally, the system had to allow the correct identification of mislabeled products, therefore not conforming, in order to allow their exclusion from the process.

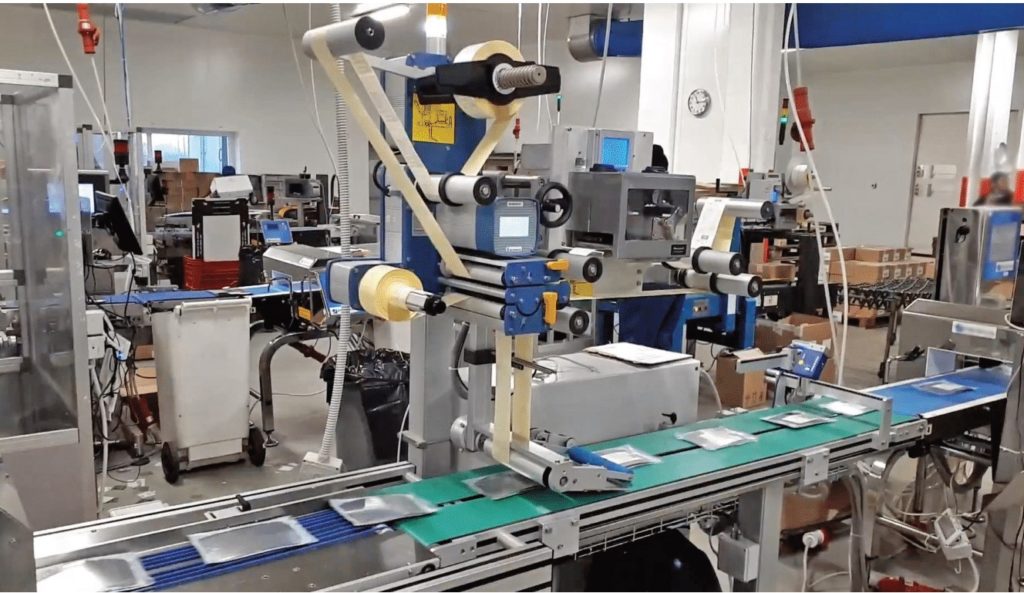

The solution: Special system 9 complete with pick&place device for distribution, barcode labeling control, non-conformity management and variable batch counting.

Etipack has designed a system based on five stations: feeding, labelling, printing and data control, product counting. Product distribution is carried out thanks to an automatic pick and place device Clippy Big, complete with high-autonomy double-belted feeding storage system.

The application of pressure-sensitive labels on the upper surface of the packages, is carried out by an Energy 200 automatic labelling machine with a distribution speed of up to 50 m/ min.

Thanks to a customized control panel, the customer can manage the coding and printing of variable data. In case of non-compliance, the system block is activated, allowing the removal of unsuitable products. At the output of the system, a batch collection and management device is installed.

System features and configurations

Thanks to the Clippy Big pick and place device, the product is positioned horizontally on the conveyor belt using a suction cup device. With the help of a fiber-optic photocell and a minimum load and empty magazine control device, the system makes it possible to detect product advancement up to the gripping base – is removable. In fact, the system integrates an aligning belt to deposit manually packaged products as well.

The labeling machine Energy 200 employed for labeling, allows to reach a label distribution speed of up to 50 m/min and to manage more than 50 operating parameters. In order to strengthen the support during the sliding of the paper, and to stabilize the transport of a label reel with a width up to 200 mm, it is also equipped with a double roller transport group.

The system allows, using a Barcode reader, to check the presence of the label applied on the product, and to interrupt the production to allow the removal in case of non-compliant product.

Thanks to a special system for collecting and managing batches, equipped with a photocell, in the final product transit station it is possible to count the correctly labelled bags in variable number, also checking the overlapping of the packages.

The control interface is customized with an integrated PLC, Industry 4.0 -ready, which allows the management of the system, the labeling process, the Barcode control and the collection of the bags at the end of the line.