The SMI Group is today one of the world’s largest producers of bottling plants and packaging machines for food and beverage, household cleaning, personal hygiene, chemical and pharmaceutical products, able to meet production requirements up to 33,600 bottles per hour.

The products handling within a “Smart Factory 4.0”

The transport of containers and products within a bottling line plays a key role in ensuring high performance standards. Today, in the era of Industry 4.0, in which the production line is characterized by machines which interact, exchange information and gather data, the transport has to be extremely fluid and precise in order to achieve a higher, more efficient and quicker production.

SMI provides innovative and versatile solutions for the handling of PET empty bottles, loose containers, packaged products and pallets inside the food and beverage production lines.

Air conveyors for empty PET containers

The first stage of the products handling within the bottling lines takes place by means of air conveyor belts. In this field, SMI offers customized solutions to transport empty PET containers of any shape and size quickly and easily from the blow molder to the filler.

SMI air conveyors are characterized by modular design, robust structure and wide operational flexibility, also thanks to the use of frequency converters (inverters) that optimize their operating speed.

Conveyors for loose products or bundles

In a bottling and packaging line, the loose containers or the packs are handled thanks to the use of proper conveyor belts made of AISI 304 stainless steel.

The key feature of SMI conveyor belts devoted to this function is represented by its

extreme ease of use by the operator during the production cycle and maintenance operations.

Thanks to the modular structure and the high compatibility with other systems, SMI products can easily and quickly perform the installation, start-up and testing operations in various types of production plants, both new and existing.

SMI conveyor belts are equipped with a wide range of chains able to handle different types of loose containers: cans, bottles, both in plastic and in glass, jars, cardboard briks and many others; moreover, they are equipped with different types of rollers in order to guarantee a fluid and regular transport of packs in multiple configurations.

The use of high quality components, together with wear-resistant materials, reduces friction and noise, preserves the quality of the packs transported and facilitates maintenance operations, with one of the best quality / price ratio in the industry.

Pallet conveyors

An efficient transport of the pallets inside a packaging line or a warehouse plays a key role in the optimization of the production process and ensures the high profitability of the plant.

SMI conveyor systems are able to handle various types of pallets (of wood, plastic, cardboard, etc.) and can be configured in roller or chain version. The modular structure of each component allows to design the line according to the space available in the plant, without compromising the fluid and precise transport required by the production program.

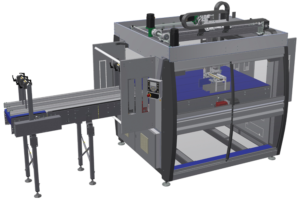

Multilane dividers for loose containers and packs

SMI provides compact, flexible systems for dividing and laning bundles and containers of non-cylindrical shape. SMI dividers are made of top-quality materials, ensuring operating reliability and long-term duration. The use of wear-resistant components reduces considerably the maintenance and cleaning operations times, thus cutting the overall operating costs.

To find out other products of the SMI range, visit the following pages:

Palletizing systems for the beverage industry

Handling systems for the beverage industry

Secondary packaging system for the beverage industry

Packaging technologies

[youtube https://www.youtube.com/watch?v=F88XVC90yg0][youtube https://www.youtube.com/watch?v=Vy2nF5FPMPs]