I’ve always loved technology that pushes the envelope. Technology that stretches our perception of the possible, shows the power of human ingenuity and tests the boundaries of the ordinary. I love technology that disrupts the way we think or do things – that shakes up markets and drives us on.

And I’m not alone. Many would say that it is a human trait – it’s as much about our will to explore, our constant curiosity and our desire to explore and learn.

And I’m not alone. Many would say that it is a human trait – it’s as much about our will to explore, our constant curiosity and our desire to explore and learn.

But new technology can be an expensive affair. Historically, surges in technology have been a byproduct of arms races, when ‘money is no object’ approaches to problem solving really set creative minds free.

Trickle down technology from previous arms races include everything from the development of codes in Roman times to the development of jet passenger travel and nuclear energy production in the 20th century.

Today, warfare and arms production remain a hotbed of technological development, but non-military fields also play a crucial role – and can be similarly expensive!

As the world works more closely together, both in the private and public sectors, in a combined effort to send humans to Mars, I have seen various arguments that the huge amounts of money involved could be better spent on other things. I also read similar things said about another interest of mine – motor racing.

So here is my brief defence of expensive technology and the positive disruption it can cause.

First – I encourage Rockwell Automation blog readers to have a look at this NASA site that looks at some of the technology, from energy saving LEDs to artificial limbs and from cordless vacuum cleaners to memory foam mattresses, that the space program has helped produce.

Meanwhile over in the fast paced world of F1, where development cycles are so short that Apple is thought to be considering buying a team to use as an R&D booster, cutting-edge racing technology continues to feed straight into road car production.

Some recent ‘trickle downs’ are discussed here, while older technologies that are commonplace in the family saloon include power steering and ABS brakes.

Beyond the automotive breakthroughs, it’s not hard to trace many modern manufacturing technologies including the development of data analytics, telemetry, and real-time diagnostics back top this cutting edge engineering.

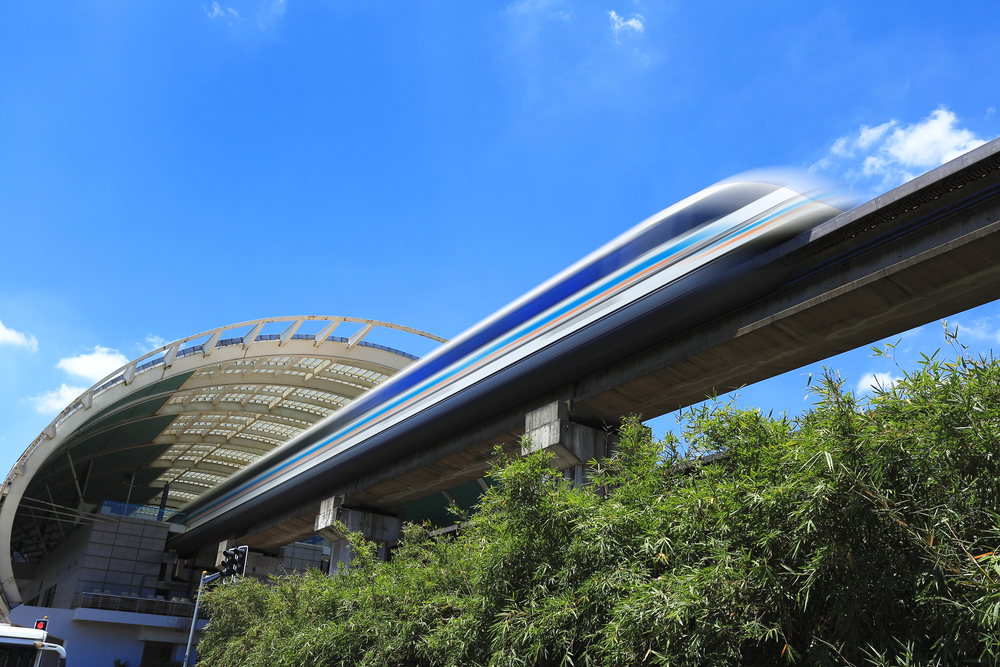

And how about a technology that didn’t quite make the difference that many expected? Back in the 60s and 70s, maglev trains that were touted to change human transport, but have only really seen a few isolated success stories at airports and the like (at least until Hyperloop really takes off…).

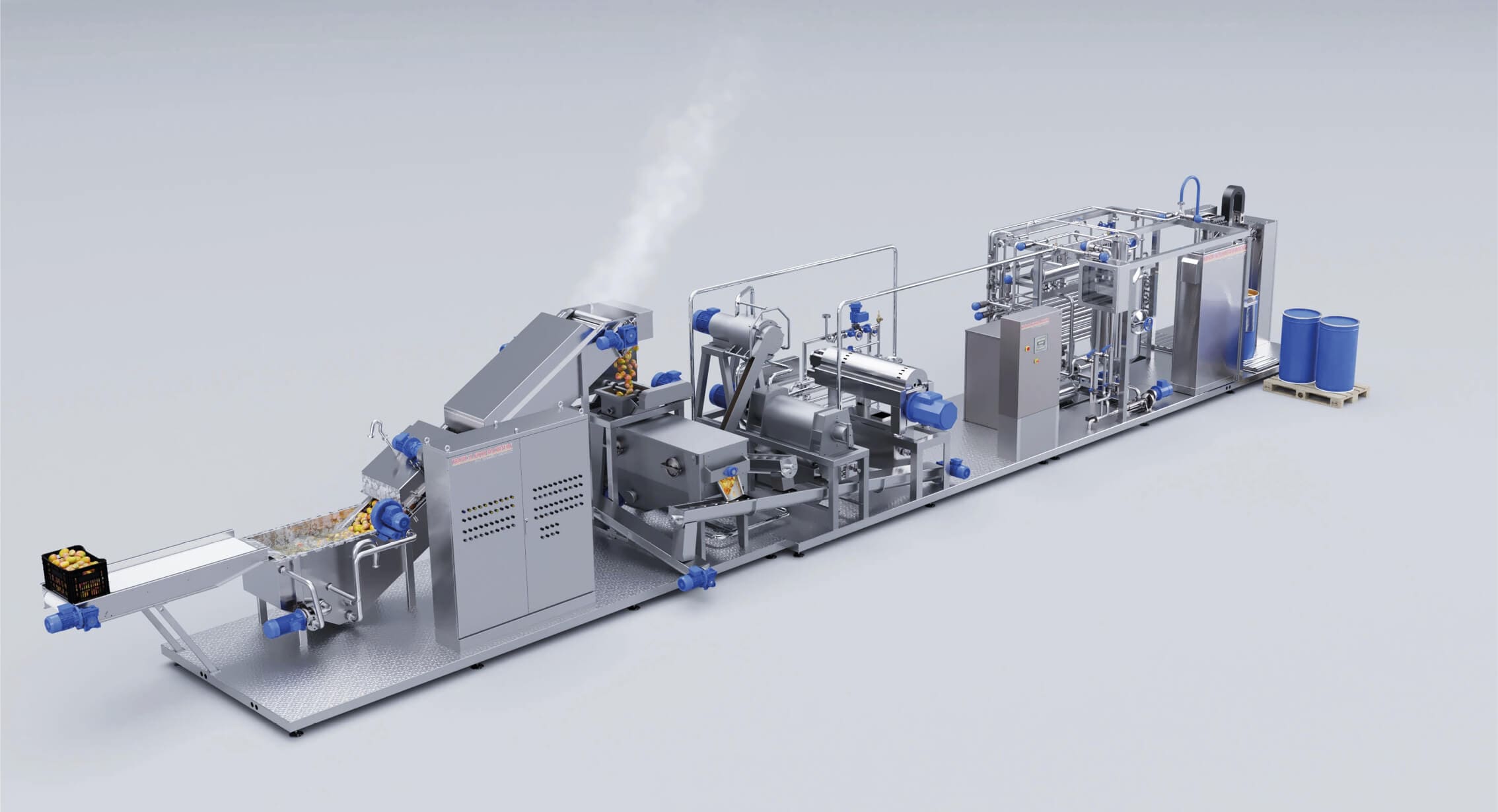

But there are interesting trickle-down applications. And one of them can be seen in this video which shows MagneMotion technology – which, alongside iTRAK, are Rockwell Automation solutions that are changing motion in industry.

And of course, it’s the maglev principles that make these solutions possible. It might be a surprise to the inventors that the technology behind controlling maglev trains can make motion in factories more efficient, smaller, more accurate, faster, more flexible and easier to control – but then I doubt that the engineers at NASA were thinking about getting a more comfortable night’s sleep when they were developing foam to absorb the impacts associated with travelling at thousands of miles an hour…

If you’d like to see more about iTRAK and MagneMotion, by the way, you can see us at interpack 2017, Dusseldorf Germany, between 4-10 may 2017, Stand A61 – Hall 6.

Author: Ulrich Arlt

Title : Product Manager Motion Control-EMEA

Company: Rockwell Automation

Email address : uarlt@ra.rockwell.com

LinkedIn profile : https://www.linkedin.com/in/ulrich-arlt-36582712/en