ULTRA POMPE S.r.l., founded in 1957, was one of the first Italian firms that completely design, produce and test external gear pumps in its own workshops. ULTRA’s success is based on satisfying customer requirement through efficient manufacturing and by providing quality products and competitive pricing. ULTRA POMPE know-how and experience has been handed down from one generation to the next. Due to this reason they have accumulated a lot of direct experience in the last sixty years.

ULTRA POMPE maintains a large inventory of standard spare parts and unassembled pumps in its own stock, allowing us to quickly provide complete pumps or replacement spare parts for customer emergency. Compact enough to quickly provide innovative custom designs, but large enough to manufacture high volumes in a short time, Ultra Pompe invests every year

in new technology for the automatization of its pro-duction lines. At today, each machinery in our fa-ctory has at least one au-tomatic backup in addi-tion to one controlled ma-nually. This allows us to avoid any production de-lays caused by machinery crashes and to meet promised delivery.

ULTRA POMPE carries on in its own premises the whole of mechanical processing, gear cutting included, thus achieving an unparalleled quality standard of the finished products. Continually up-dating out technology and products designs al-lows ULTRA POMPE to provide the right gear pump or system for a va-riety of processes and li-quid, semi-fluid or emul-sions. Using of UNI/ISO /ANSI/DIN/MEC dimen-sion significantly increa-se the possibility to meet all customer requests.

GEAR PUMPS – EASY VIEW

These gear pumps are used from 1 up to viscosity 1’000’000 cSt. In the operating scheme is shown how the rotations of the gears displace the product from the inlet side to the outlet side. The entire operation can be resumed in three main phases: Suction, Delivery and Discharge. Into a gear pumps the two rotors, that are respectively called driving and driven rotor, are seated in a body that round them from all side.

On the both sides of the mesh zone of the teeth there is a hole in the body of the pump. These holes are respectively called suction and discharge.

Spinning the rotors the fluid is moved, through the chambers between the teeth of the rotors and the body, from the suction side to the discharge side.

Fluid does not pass through the meshing zone of the gears due to small tolerances. A back-flow of the fluid is blocked by the contact of the teeth of the two rotors in the meshing zone.

ADVANDAGE

Gear pumps need a lesser NPSH and have better properties of delivery repeatability. Gear pumps, being rotary volumetric pumps, are the best metering pumps, since their delivery depends directly on the revo-lutions rate. Also gear pumps will not generate flow pulsations, as standard metering pumps do, making the media flow constant.

MAIN SECTORS

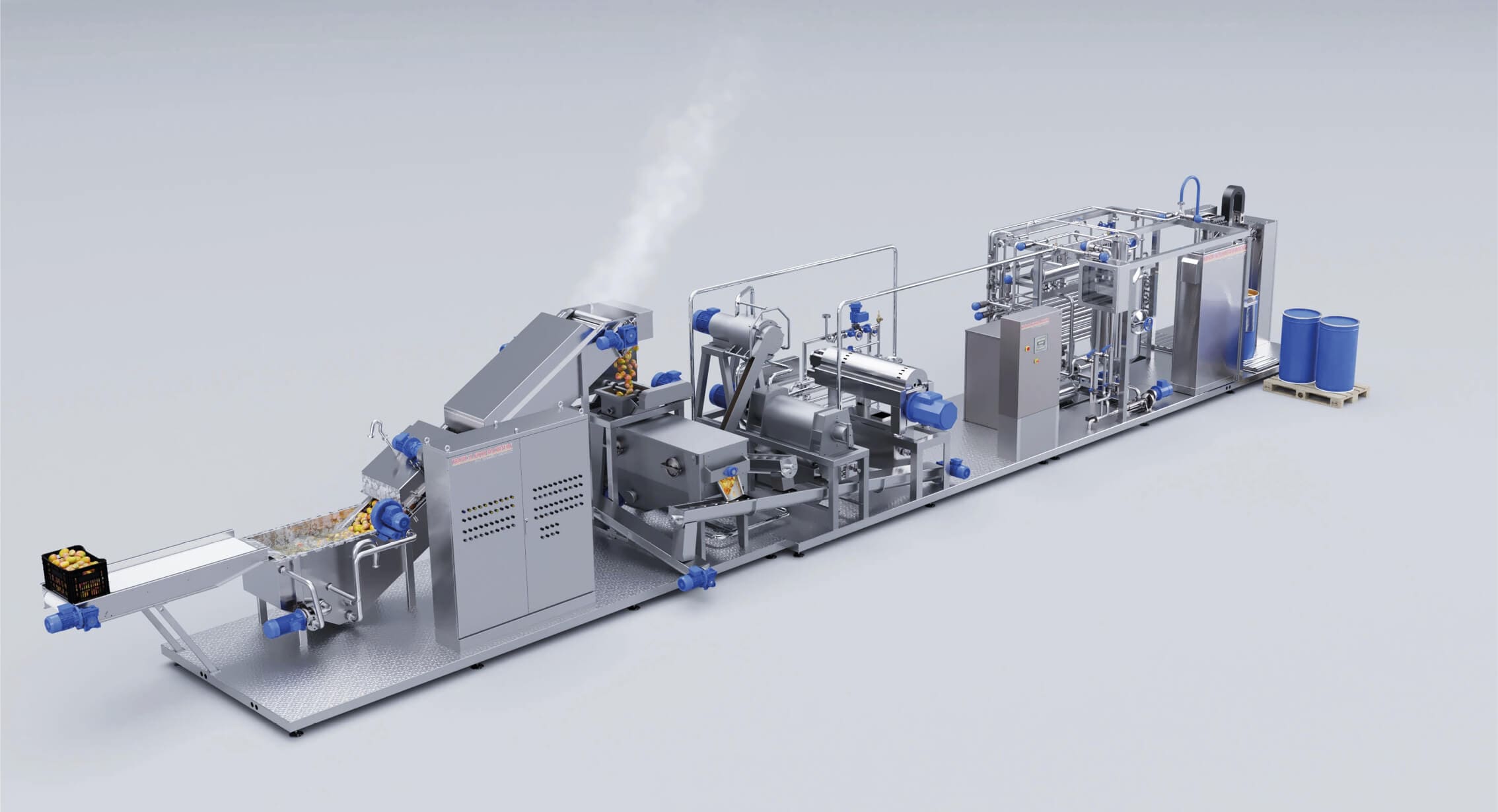

Oil Frying Pumps

Palm & Seed Oil Pumps

Chocolate Pumps

Base Food Pumps

Aromatics Pumps.

www.ultrapompe.it

sales@ultrapompe.it