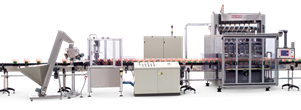

OCME srl - FILLING MACHINES FOR BEVERAGE INDUSTRY

A bottle is filled when the liquid is transferred from the tank to the container filling machines for beverageindustry. What distinguishes one filling technology from another is the way in which the correct quantity of product is supplied.

Different systems and different technologies may be used. Principally, these may be divided into three categories: filling by level sensing, using volumetric flow meters by weight.

By level sensing: these filling machines for beverageindustry are the most traditional and commonly used types of filling machines. The fill level is determined by the lenght of the tube that enters the bottle, during the filling stage. Generally speaking, to change the level in a bottle, the tube must also be changed.

By flow meters: these types of filling machines measure the volume of product eentering the bottle. A flow meter (with either a mass or magnetic indicator) fitted on every filling nozzle gauges the volume. These are called electronic filling machines for beverageindustry.

Of these filling machines for beverageindustry systems, the level sensing system is consolidated by years of use in the beverages sector, as it is predominantly tied to mechanical devices. Ocme machines for the beverage industry use both level technology and electronic weight technology or volumetric flow meters. In the latter two cases, a sensor (which may either be a scale with a load cell or a mass or magnetic indicator, depending on the technology used) enables or interrupts the flow of product towards the bottle, so as to obtain the correct amount of product inside the container, based on the production settings.

Ocme over the years has

developed the following fillers:

- Lynx: is the range of fillers dedicated to product such as personal care, home care, edible oil, lubricating oil and chemicals. Containers handled can be bottles or cans, made of plastic, glass or metal with volumes varying between 50ml and 5 litres. Lynx adopting the technology of volumetric piston filling.

- Libra: is the line created for using viscous liquid using the electronic weight filling technology. It could be: rotary weight filler (containers handled: bottles or tins made of plastic, glass or metal with a volume ranging from 50 ml to 5 liters or plastic or metal pails with a volume ranging from 10 liters to 30 liters) or in–line weight filler(containers handled: drums or pails made of plastic or metal with a volume ranging from 60 liters to 200 liters).

The Ocme series of filling machines consents choosing the right technology to handle a vast number of products, both strictly for beverages as well as for other food liquids of various types.

To choose the ideal machine, various factors must be considered, such as for example, the type of product, the type of container and the material used for the container, but also the degree of precision required and the production volume. The Ocme series of filling machines for beverageindustry is designed to cover a wide range of possibilities, allowing companies in the beverages sector to cover everything from small or medium production volumes to large or very large volumes.

Thanks to its long-standing experience in the beverages sector, Ocme can provide customers with complete support for turnkey solutions. The main machines included on the beverages line are designed and manufactured by Ocme, providing a further guarantee of the highest quality standards and minimal integration difficulties. Ocme places entire teams of specialized engineers at the service of its customers to develop solutions that respond to specific bottling and handling needs.

Each filling machines for beverageindustry manufactured by Ocme and any integrated device manufactured by external suppliers are the result of accurate studies and a rigorous selection process, with the sole aim of guaranteeing that the performance demanded by each customer is fully met.

To see other products of the OCME Srl, visit the following pages:

- Food industry palletizing systems

- Handling systems for beverage industry

- Secondary packaging systems for beverage industry

- Packaging machinery

- Filling machines for beverage industry