OCME srl - HANDLING SYSTEMS FOR BEVERAGE INDUSTRY

OCME AND INTERNAL LOGISTICS: INNOVATIVE HANDLING

OCME is a long-time player in the field of automated handling systems for beverage industry and internal logistics. The growth in this sector, in terms of both sales and applied technologies, has gained increasing momentum in recent years, thanks to the development of laser-guided vehicles and to logistics control and integrated management technologies.

In handling systems for beverage industry field, OCME has decided to operate in an absolutely independent manner, without depending on external partners or third party technologies in general. OCME has pooled all the necessary know-how from specialists and engineers who are experts in this sector. Their experience and high level skills have allowed OCME to create a new and important Handling Business Unit, in record time and with innovative products, immediately gaining positive customer response.

The logistics project were based on the desire to assert OCME as a full-service supplier for all automated handling, packaging, palletising and filler technology solutions. It is no coincidence that the company motto, “moving ideas”, conveys the company vocation for dynamism and drive.

However, handling systems for beverage industry does not mean merely manufacturing good vehicles or good hardware in general. Understanding all real customer needs, foreseeing new scenarios for future development and organising a complex project capable of interacting with pre-existing systems and infrastructures requires considerable engineering know-how in various different fields. In this sense, OCME can rely on half a century’s worth of competencies and experience in handling systems for beverage industry, acquired in most major industries the world over.

The OCME production programme in the field of logistics and handling systems for beverage industry comprises:

Integrated management and control system

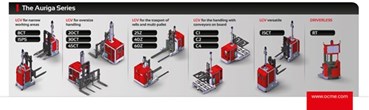

Auriga LGV laser-guided shuttles

Track-vehicles

Conveyors lines

Of all available handling systems for beverage industry, laser-guided navigation is both the easiest to install and the one that provides greatest flexibility of operation. Hence, OCME has chosen this solution to provide Auriga with a highly reliable drive and route correction system.

Laser-guided navigation uses special reflective targets fitted to the walls of the shuttle working area, to provide a reference grid for shuttle orientation and steering. In fact, this type of system does not require the installation of any fixed or movable structures on the plant floor.

Changes to be made to the layout of the bay do not entail any site modifications, but simply require adjustments to the management software; indeed, the vehicles are designed to accept new routes and orders originating from the control system. Unlike other, less flexible navigation systems, automatic laser-guided shuttles can auto-determine the best route to follow to complete a given mission and are aware of the position of all other vehicles in the fleet, so as to avoid collisions.

The Auriga series of laser-guided vehicles is composed of three standard models with a loading capacity of between 1,000 and 6,000 Kg. Two main variations of the model are also available: a lifting vehicleand conveyor-equipped vehicles, mainly used for product transfer. A series of optional features allow the creation of vehicles that may perfectly fulfill the specific requirements of any company, in terms of both loading capacity and versatility. Lifting vehicles may be provided with equipment suited to handle from one to up to eight pallets simultaneously.

Forks may be short, long or telescopic, with fixed or adjustable format, according to the type of load handled.

Conveyor-equipped vehicles may be provided with rollers, chains or belts, according to the specifications of the loads to be handled. Vehicles may be lateral-load or rear-load shuttles; both loading systems deliver the

maximum precision and optimum safety standards guaranteed by OCME Auriga systems.

All Auriga vehicles can be equipped with the following features: telescopic laser, load pressstabilisers, additional load weight control and safety packages.

To see other products of the OCME Srl, visit the following pages:

- Food industry palletizing systems

- Handling systems for beverage industry

- Secondary packaging systems for beverage industry

- Packaging machinery

- Filling machines for beverage industry