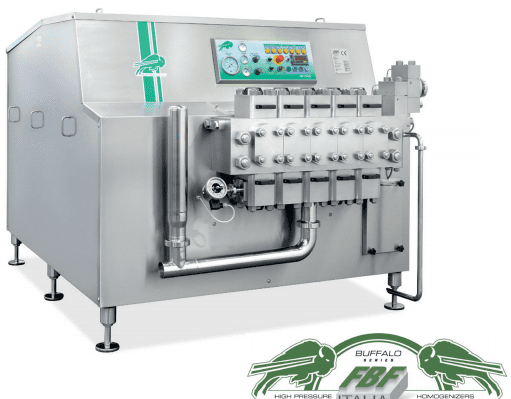

FBF Italia’s machines are suitable to process a lot of products and can be inserted into complete process/production, both in sanitary and aseptic design

FBF Italia has designed and manufactured since 1987, high-pressure homogenizers, positive displacement pumps, laboratory homogenizers and, thanks to the wide experience gained in this field, is now a key point-of-reference for plants manufacturers, suppliers of turn-key equipment and end-users in the food, chemical, and pharmaceutical sectors

FBF Italia has designed and manufactured since 1987, high-pressure homogenizers, positive displacement pumps, laboratory homogenizers and, thanks to the wide experience gained in this field, is now a key point-of-reference for plants manufacturers, suppliers of turn-key equipment and end-users in the food, chemical, and pharmaceutical sectors

On-going innovation, exacting experimentation of special materials, strict quality controls and endurance tests allow FBF Italia to guarantee maximum performance, durability, reliability, and safety; its mission is to offer to all its customers not only excellent sales services but also continuous relationship with constant, direct post-sales technical assistance; the target is to keep a friendly relationship built on mutual evolution and innovation

FBF Italia’s machines are suitable to process a lot of products and can be inserted into complete process/production, both in sanitary and aseptic design. The main utilization fields of the company machinery are:

- dairy industries (milk, cream, cheese, yoghurt, caseinates, proteins, soya milk, etc.);

- ice-cream industries;

- food, processing, preserving and beverage industries (fruit juices, tomato sauces, oil, ketchup, eggs, vegetable greases, emulsions, concentrates, baby food, etc.);

- cosmetic, pharmaceutical, chemical and petrol-chemical industries (starch, cellulose, wax, colorants, beauty creams, toothpaste, detergents, disinfectants, emulsions, inks, latex, lotions, emulsifiers oils, pigments, proteins, resins, vitamins, etc.).

But what about the homogenizing principle? In order to permanently mix one or more substances in a liquid, a homogenizer must be used in such a way as to make it possible to micronize and disperse the suspended particles in the fluid, rendering it highly stable even during successive treatments and storage.

The product reaches the homogenizing valve at a low speed and at high pressure. As it passes through the valve, it is subject to various forces that cause the micronization of the particles: violent acceleration followed by immediate deceleration causes cavitation with the explosion of the globules, intense turbulence together with high-frequency vibrations, impact deriving from the laminar passage between the homogenizing valve surfaces and consequent collision with impact ring.

Homogenization can occur with the use of a single stage homogenizing valve (suitable for dispersion treatment), or double stage homogenizing valve (recommended for use with emulsions and for viscosity control when requested).

FBF Italia’s range of machines can be commonly classified as follows:

High-pressure homogenizers

Positive displacement pumps

Laboratory homogenizers

Positive displacement pumps for a product containing particles.