Based in Italy I.M.A.R. company is specialized in manufacturing ovens for the production of molded ice cream cones, cups, and wafer products and take-away containers in a wide variety of shapes, from the shape of a fish or a corncob to a flower or even a bear, also using gluten-free or vegan batter.

Delicious ice cream cones and cups, custom-made, also vegan and gluten-free. Waffle-based products are 100% eco-friendly.

They can replace plastic products, as they are completely biodegradable and edible at the same time. We have been producing wafer baking machines and molds since 1947, selling them all over the world and we keep growing with our long work experiences in this field.

We are 11 people working inside IMAR premises, where we have our Research & Development division with two engineers and one project manager, so that we can offer a design and engineering dedicated to each client.

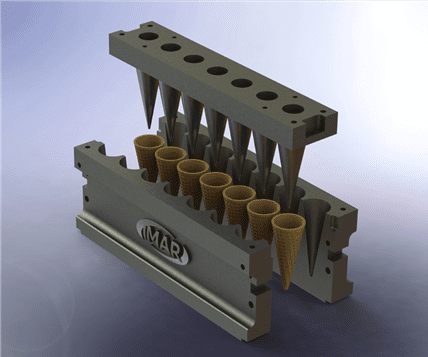

At IMAR we also manufacture the molds and we assemble the equipment; and then we directly co-operate with two companies nearby IMAR for the manufacturing of some parts of the machine.

Our machinery fulfill any production rate (from 2000 pcs up to 8.000 pcs/h) and wafer products can have any shape and dimension (upon customer request and/or drawing).

Five models are available:

– type AML 14 complete with a set of 14 moulds, production rate from 2.000 to 3.600 pcs/h,

– type AML 18, complete with a set of 18 moulds, production rate from 2.600 to 4.500 pcs/h

– type AML 21, complete with a set of 21 moulds, production rate from 3.000 to 5.300 pcs/h

– type AML 28, complete with a set of 28 moulds, production rate from 4.000 to 7.000 pcs/h

– type AML 36, complete with a set of 36 moulds, production rate from 5.000 to 8.000 pcs/h

Production rate can be calculated according to the diameter of the cone/ cup.

Each machine has a Remote Control Device installed, so that we, from our office in Italy, can connect to the oven, to the PLC of the oven, in the event of problems or malfunctioning and help the customer to solve any issue.

After-sale Service, with our dedicated office, is also another important issue that we really care about. Just tell us about your project

This is the way we work, STEP BY STEP:

(1) Together with the customer we decide shape and dimensions of the cone.

(2) IMAR prepare a drawing.

(3) If the customer likes the drawing, we make a few samples with our 3D printer and we send them to the Customer.

(4) Once the Customer places the order, we make some real samples and we send them to the Customer. Customer checks the samples. At this stage any variation on the cone is still possible.

(5) Only after Customer’s approval we start manufacturing the Molds, because we want our Customers to have exactly the product they like.