Sweet Condensed Milk first appeared in France in the middle of the 19th Century thanks to the genius of Nicolas Appert, who developed the recipe, and the entrepreneurial spirit of Gail Borden and the Page brothers who understood the potential of an easy-to-preserve-and-distribute dairy product.

Since then, the product has achieved great success and has become part of the culinary culture of many countries:

• In Mexico and in the USA, it is very popular as a base ingredient of many desserts and cakes,

• In Brazil you can’t have a real birthday party without “brigadeiros” – sweet small pieces of patisserie, 70% made of sweet condensed milk,

• If we think about Argentina one of the first things that pops in to our mind is the famous “dulce de leche”, which is almost an ambassador for the Argentinian culture,

• In the Far East everybody is crazy about red beans ice cream, where the azuki beans merge perfectly with sweet condensed milk.

• And last but not least, in Spain, thanks to the presence of many people from Latin America, sweet condensed milk is used to prepare churros

In addition to these established markets, the wider global market is expanding too, especially in West Africa and Middle East. This is thanks to the stability of the product, with its resistance to high temperatures and its suitability for logistic scenarios involving long distances without the presence of an effective Cold Chain.

Its stability is thanks to an evaporation process, which reduces its water content, prior to quick pasteurization at 90°C for few seconds, which reduces the remaining bacterial load. The added sugar also increases the osmotic pressure, preventing further bacterial proliferation.

A stable product that doesn’t require any sterilization once canned could lull some customers into a false sense of security, thinking they don’t need to pay too much attention to hygienic design. But this naive approach could result in a lot of unexpected problems in terms of product oxidation and reduced shelf life, to name but a few.

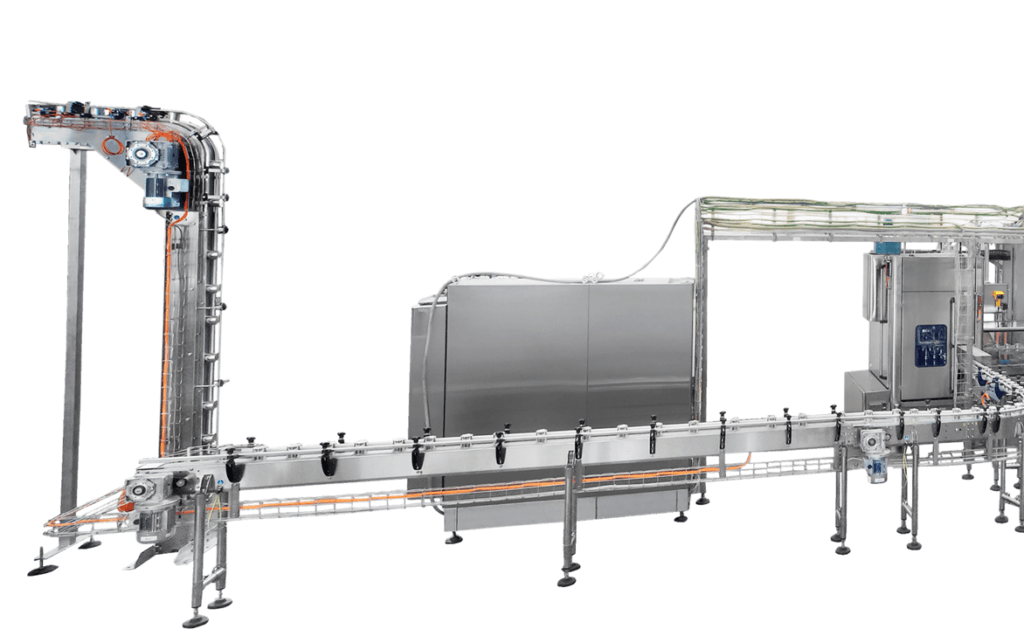

A best-practice filling and packaging line will first focus on cleaning the empty cans and lids, to achieve two essential goals: reduced bacterial load and the prevention of undesired condense residuals, which could dilute the product and jeopardize its stability.

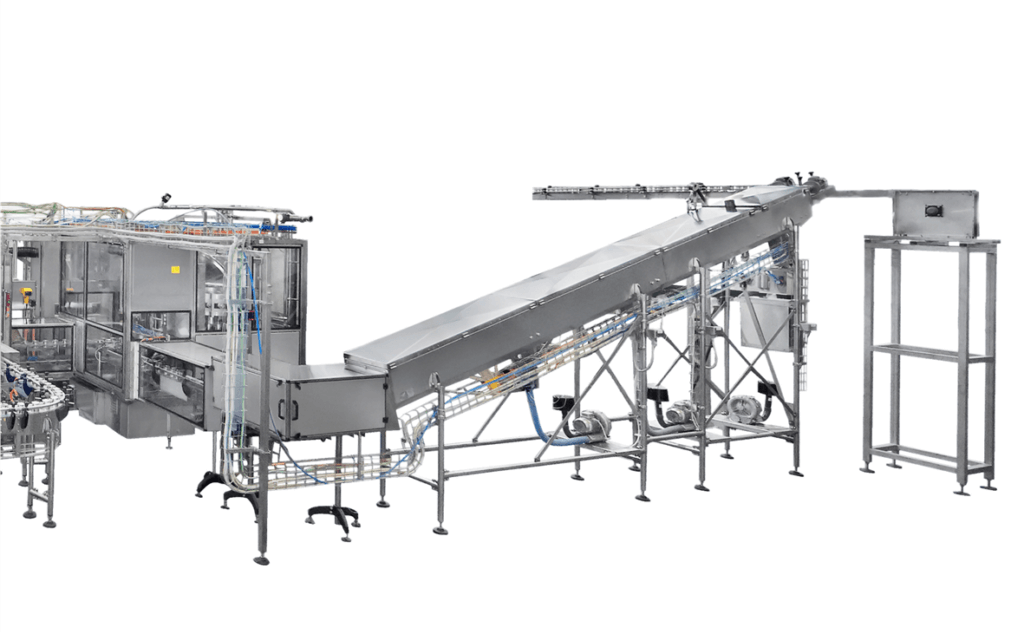

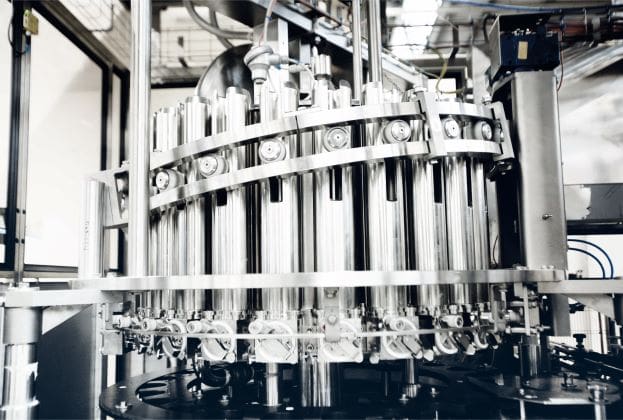

We must also consider the viscosity of the product. Sweet condensed milk is very viscous, whereas evaporated milk – which is often produced on the same line – is very foamy. Therefore, a properly designed piston filler is the perfect answer to the different demands of these two products.

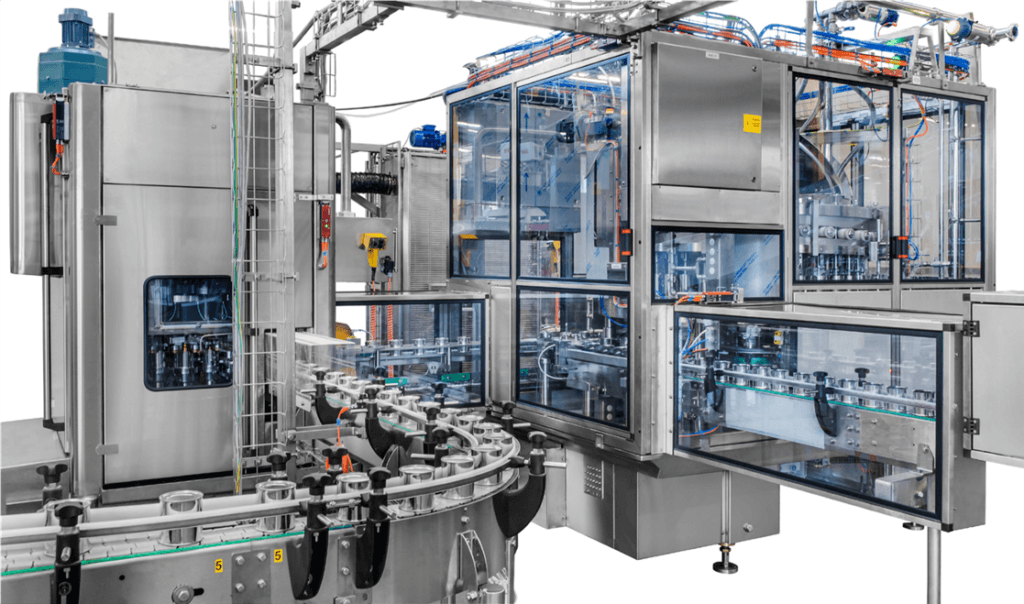

Experience also teaches us that a properly protected filling environment and a fully cleanable filling machine helps a great deal towards consistent and efficient production.

Last but not least, don’t forget that sweet condensed milk’s first enemy is oxidation, therefore a seamer designed to close cans in a protected environment is always a good choice. The cleanability of this machine plays an important role too, not just in hygienic terms, but also for the line efficiency.

Sweet condensed milk is a very sticky product, which can cause more than basic discomfort in a line that is not cleaned or maintained properly.