INTERPACK 2014

[twitter-follow screen_name=’itfoodonline’]

Tweet

Tweet #INTERPACK 2014

For info please contact +39 0362 244182, or mail to info@itfoodonline.com.

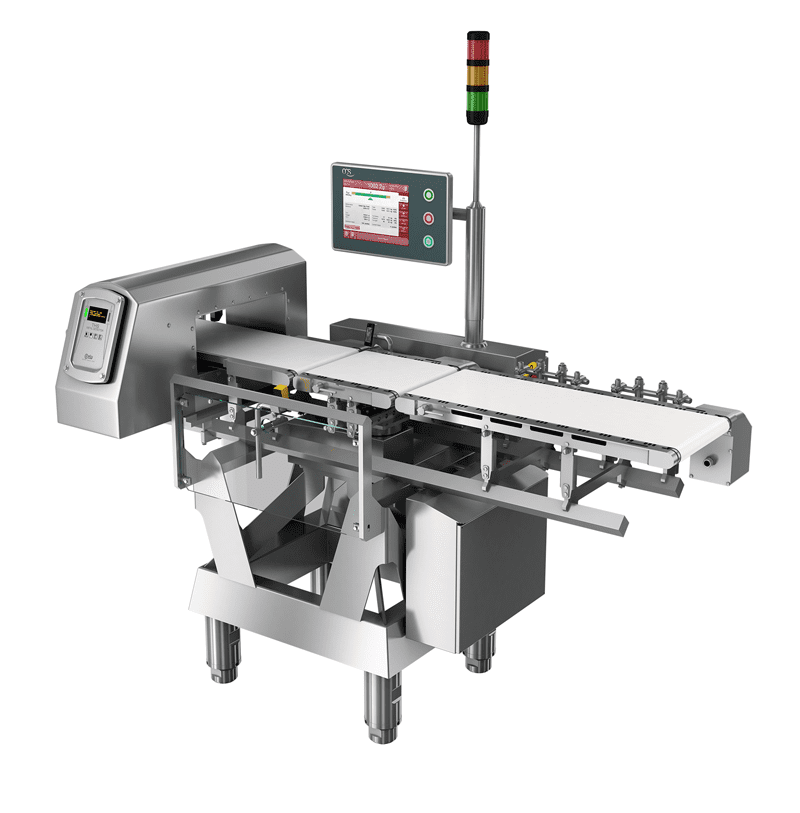

Excellent Product Inspection from OCS – Discover simplicity at work

OCS Checkweighers shows its widest product portfolio ever at interpack 2014

During the 20th interpack edition (08 – 14 May 2014) OCS Checkweighers will showcase its most comprehensive product portfolio ever. Covering almost twice the size as their previous stand from interpack 2011, OCS will answer every aspect of current and future application needs. With OCS’s broad range of inspection solutions for weighing, scanning and verifying, the highest requirements of the packaging industry are perfectly served.

During the 20th interpack edition (08 – 14 May 2014) OCS Checkweighers will showcase its most comprehensive product portfolio ever. Covering almost twice the size as their previous stand from interpack 2011, OCS will answer every aspect of current and future application needs. With OCS’s broad range of inspection solutions for weighing, scanning and verifying, the highest requirements of the packaging industry are perfectly served.

Dynamic Weighing: 100% inline weight control up to 640 ppm

OCS categorise its checkweighers in three product lines: Essential (EC-E), Medium (HC-M) and Avantgarde (HC-A). Each machine is designed to be easily and conveniently integrated into existing production lines. Each machine stands for an excellent performance. Whilst ensuring the highest reliability, these checkweighers are reading the individual product weight, verifying the reading against the set weight value and rejecting all incorrect weight units automatically. The HC-M and HC-A family offers a huge model variety which is driven by the market demands. The HC-M-WD (protection class IP 69K) for example is made for intensive wash down cleaning regimes and strict hygiene requirements. Self-evident it complies to the HACCP and IFS regulation.

OCS categorise its checkweighers in three product lines: Essential (EC-E), Medium (HC-M) and Avantgarde (HC-A). Each machine is designed to be easily and conveniently integrated into existing production lines. Each machine stands for an excellent performance. Whilst ensuring the highest reliability, these checkweighers are reading the individual product weight, verifying the reading against the set weight value and rejecting all incorrect weight units automatically. The HC-M and HC-A family offers a huge model variety which is driven by the market demands. The HC-M-WD (protection class IP 69K) for example is made for intensive wash down cleaning regimes and strict hygiene requirements. Self-evident it complies to the HACCP and IFS regulation.

OCS machinery leads the way with sophisticated servo drive conveyor technology, to ensure perfect product handling. The technology in the servo drives is second to none and benefits from being practically maintenance free. Product handling is key to customer success. The same can be said for the unique Weigh Cells based on Electro Magnetic Force Restoration, with distinct competitive advantages such as AVC technology. AVC (Active Vibration Compensation) allows the precise dynamic weighing in even the worst vibration affected environments. AVC is cleverly utilised to compensate for background vibration to ensure consistently accurate weight readings. This technology is not only come handy in weak building structures or heavy forklift traffic but even when running speeds over 400 ppm.

OCS machinery leads the way with sophisticated servo drive conveyor technology, to ensure perfect product handling. The technology in the servo drives is second to none and benefits from being practically maintenance free. Product handling is key to customer success. The same can be said for the unique Weigh Cells based on Electro Magnetic Force Restoration, with distinct competitive advantages such as AVC technology. AVC (Active Vibration Compensation) allows the precise dynamic weighing in even the worst vibration affected environments. AVC is cleverly utilised to compensate for background vibration to ensure consistently accurate weight readings. This technology is not only come handy in weak building structures or heavy forklift traffic but even when running speeds over 400 ppm.

X-ray Scanning: much more than simple contamination detection

..The appreciated application flexibility from the checkweigher range is also implemented in the comprehensive product portfolio of sophisticated X-ray scanners. The best possible product inspection is guaranteed by utilising a modular machine design and an intelligent but unique X-ray inspection approach. Scanners by OCS Checkweighers fulfill highest requirements with regards to precise detection and ensure best possible food safety. These scanners not only detect foreign objects and other contaminants such as stones, eventually glass, plastics and bones with a higher density. But furthermore, they detect product flaws such as broken, deformed or incomplete products and rejects them. The unique camera-detector-technology renders product pictures of stunning sharpness and resolution (as high as 0,15 mm). Taken images can be stored and kept for further reference. Additionally with its modular design the OCS X-ray range helps customers with bespoke requirements. For example the X-ray is fitted with a closed water cooling loop that is both compact and can be fully flexible in design.

..The appreciated application flexibility from the checkweigher range is also implemented in the comprehensive product portfolio of sophisticated X-ray scanners. The best possible product inspection is guaranteed by utilising a modular machine design and an intelligent but unique X-ray inspection approach. Scanners by OCS Checkweighers fulfill highest requirements with regards to precise detection and ensure best possible food safety. These scanners not only detect foreign objects and other contaminants such as stones, eventually glass, plastics and bones with a higher density. But furthermore, they detect product flaws such as broken, deformed or incomplete products and rejects them. The unique camera-detector-technology renders product pictures of stunning sharpness and resolution (as high as 0,15 mm). Taken images can be stored and kept for further reference. Additionally with its modular design the OCS X-ray range helps customers with bespoke requirements. For example the X-ray is fitted with a closed water cooling loop that is both compact and can be fully flexible in design.

Advantage built-in: Excellence by in-house development & manufacturing

The extraordinary manufacturing depth and the setup of all design and production steps under one roof guarantees the exceptional quality, flexibility and reliability of OCS Checkweighers’ whole array of products. OCS customers benefit from the fact that all key components and the systems themselves are manufactured entirely in-house. This allows direct communication, perfect customisation to individual needs and a future proofing investment with a guaranteed spare parts service where needed many years down the road.